PES CY DYNAMIC ROD-LOCKING DEVICE

4

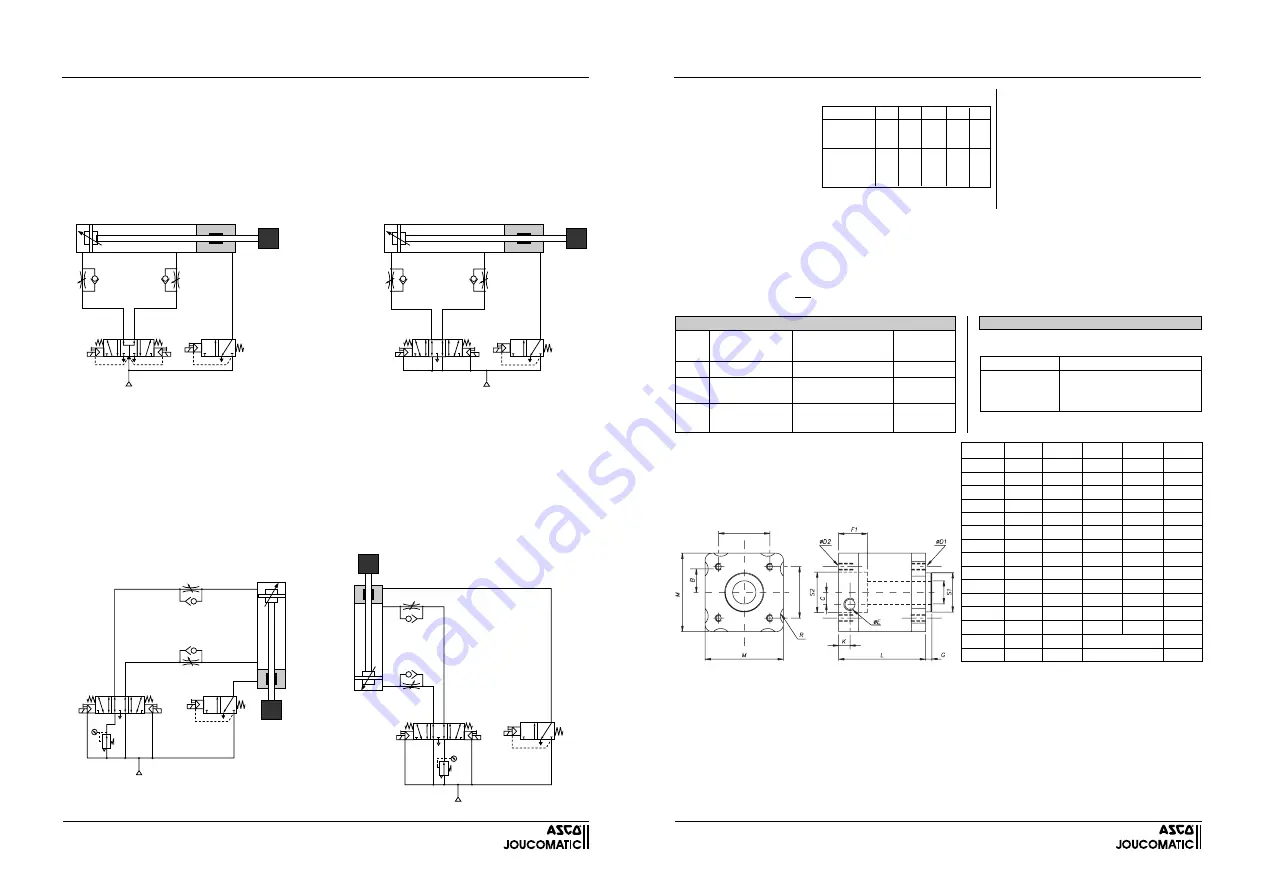

HORIZONTAL MOUNTING

The cylinder is controlled by a 5/3 valve (ISO size 1 for diameters 40 and 50 mm, ISO size 2 for diameters 63, 80 and 100 mm), with

centre open to the central port (type W2 - fi g.1), or centre open to exhaust (type W3 - fi g.2), and supplied by exhaust ports 3 and 5. In

both options, the pressure is maintained on both sides of the cylinder piston and the forces exerted on it are balanced. This prevents

any accidental movement of the rod when it is disengaged. Type W2 is recommended for its simpler wiring. Do not use a 5/3 valve with

closed centre (type W1), since this will unbalance the piston in case one of the components in the circuit leaks.

NOTE

: The cylinder rod may move out slowly after release of the system as a result of the “rod effect”.

One-directional fl ow reducers must be used to control the rate of speed of the rod.

The rod lock device must be activated by a 3/2 NC solenoid valve, with a minimum passage diameter of 8 mm, to ensure fast braking

of the cylinder rod. Locking by absence of air.

VERTICAL MOUNTING

The cylinder is controlled by a 5/3 valve (ISO size 1 for diameters 40 and 50 mm, ISO size 2 for diameters 63, 80 and 100 mm), with

centre open to exhaust (type W3), and supplied by the exhaust ports. To ensure that the lock functions properly, the force on the piston

which is generated by pressure - and which operates in the same direction as the load - must not exceed the locking capacity of the

device when it is combined to the force of the load (see table on opposite page).

Do not use a 5/3 valve with closed centre (type W1) since this will unbalance the piston in case one of the components in the circuit

leaks. This could be hazardous when the rod is disengaged.

Use of a 5/3 (type W3) valve provides a braking effect and ensures that the rod is held in a given position. The stopping precision

depends on the rate of speed of the rod and the loads in motion.

One-directional fl ow reducers must be used to control the rate of speed of the rod.

The rod lock device must be activated by a 3/2 NC solenoid valve, with a minimum passage diameter of 8 mm, to ensure fast braking

of the cylinder rod. Locking by absence of air.

Fig. 2 - Cylinder control with a 5/3 valve,

centre open to exhaust (type W3).

Fig. 1 - Cylinder control with a 5/3 valve,

centre open on central port (type W2).

2

2

4

12

14

1

3

3

5

1

W

2

2

4

12

14

1

3

3

5

1

W

Lowering

control

Lifting

control

Lifting

control

Lowering

control

Fig. 3 - Load

underneath

the cylinder

Fig. 4 - Load

on top of

the cylinder

2

2

4

12

14

1

3

3

5

1

W

Extend

control

Retract

control

2

2

4

12

14

1

3

3

5

1

W

Retract

control

Extend

control

DYNAMIC ROD-LOCKING DEVICE Ø 16-20-25 mm

(Rod-locking device alone)

5

MECHANICAL CHARACTERISTICS

Ø rod (mm)

Holding

force (N)

Speed : 0.5

(m/s)

0.2

16 20 20 25 25

1000 1600 2500 4000 6300

80 130 200 320 500

90 145 225 360 590

FLUID

: Air or neutral gas,

fi ltered, lubricated or not

LOCKING SIGNAL

Min. pressure : 4 bar

Max. pressure : 8 bar

MAX SUPPLY PRESSURE FOR

ROD LOCKING DEVICE

: 8 bar

PNEUMATIC CHARACTERISTICS

HOLDING FORCE (static) :

RESTRAINING CAPACITY

:

Max. load (kg)

that can be stopped dynamically over a distance of 50 mm in

relation to the rate of speed of the rod (the rod must be in vertical position).

RATE OF SPEED OF THE ROD : max. 0.5 m/s

ROD CHARACTERISTICS : see below

IMPORTANT RECOMMENDATIONS

- The rod must have the following characteristics:

-

The rod-locking device must be centered on Ø S1 or S2

•

Dimensional tolerance: h9

(see dimensions below).

•

Hard-chrome plating or hard coating

•

R

•

600 N/mm

2

and Rt = 5 µm

•

There must not be any sharp edges

DIMENSIONS AND WEIGHTS

Ø rod (mm) 16 (h9) 20 (h9)

20 (h9) 25 (h9)

25 (h9)

(2)

N

1000 1600

2500 4000

6300

M

70 75

95 95

120

TG

38 46,5

56,5 72

89

G

4 4

4 4

4

F1

24 30

30 36

40

L

95

112 120

140 150

R

7 -

8 -

-

B

18 -

25 -

-

C

-

12

- -

-

ØE

G1/8 G1/4 G1/4 G1/4 G1/4

K

15,5

22,9

15

21 21

ØD1 M6x13

M8x13 M8x14

M10x28 M10x28

ØD2 M6x13

M8x13 M8x13

M10x34 M10x37

ØS1 Ø35

Ø40

Ø45

Ø55

ØS2 Ø35

Ø40

Ø45

Ø55

(2) : Static holding force (N)

-0.05

-0.1

-0.05

-0.1

-0.05

-0.1

-0.05

-0.1

+0.1

+0.05

+0.1

+0.05

+0.1

+0.05

+0.1

+0.05

TG

TG

Ø MM

Weight of rod-locking device alone (light alloy body)

Model

1000 N : 1.3 kg

1600 N : 1.5 kg

2500 N : 3.1 kg

4000 N : 3.5 kg

6300 N : 5.6 kg

20

1000

88145265

Ø 40

1600

88145266

Ø

50

2500

88145267

Ø 63

4000

88145268

Ø

80

6300

88145269

Ø

100

25

16

Ø rod (mm)

CODES

16

(h9)

88145276

(1)

20 (h9)

88145277

(1)

25 (h9)

88145278

(1)

(1) Length (m) to specify on order (max. length: 3 m).

The rod can be delivered as follows:

ROD

ROD-LOCKING DEVICE

Ø rod

(mm)

Static holding

force (N)

CODE

ROD-LOCKING

DEVICE alone

Mountable

on PES

cylinder/tie rods

ORDERING INFORMATION

PUTTING INTO SERVICE - MAINTENANCE

- Before installing the rod-locking device, it must be pressurised (min. 4 bar, max. 8 bar) to release it. Introduce the rod into the

locking device, taking the following precautions:

•

There must not be any sharp edges on the rod

•

The rod must be perfectly aligned with the centreline of the locking device

•

There must be no point of resistance

- Before fastening the rod-locking device on its mounting support, depressurise the locking device so that it can be centered

correctly on the rod.

- The rod locking device is fi tted with 2 wiper seals made of PUR. It is recommended to grease the rod lightly at regular intervals

with a non-detergent class ISO VG 32 oil without aggressive additives (commonly used in pneumatic circuits). Do not let the

rod come into contact with any other oils or products which might damage the wiper seals made of PUR.

-

It is recommended to check the correct operation of the rod-locking device at regular intervals.