OPERATING AND MAINTENANCE MANUAL FU 321M

22

COOLING SYSTEM

The cooling system consists of a coolant tank, a motor pump and a spout. The

tank is situated in the base of the machine.

The quantity of the cooling liquid is about 50 l.

The base of the machine is provided with a tray whose purpose is to collect the

coolant from the slides and the knee.

Coolant prolongs the life span of the cutting edges and improves the finish of the

machine surfaces. Not only should these factors to taken into account on choosing

a coolant type, but the damage it can do to the paintwork of the machine and

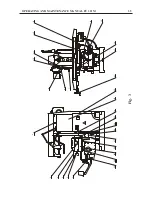

rust it can cause to exposed metal surfaces as well. The motor pump situated at

the back part of the column is started by a switch "Coolant ON/OFF" / Pos.44,

Fig.3a / on the control panel.

The coolant driven by the motor pump is pumped to the spout at the front part

of the column. The spout can be adjusted to any position and remains in this

position with required angle.

The spout has a cylindrical part with a double function - shut-off cock and setting

of the coolant flow by means of turning the tap. Even if the motor pump is ON

there is no problem in having the tap closed

Recommended Coolants

Mobil - Mobilcut 262

If coolants are used from another firms it is recommended COSHH sheets.

Warning:

When working with materials that may be flamable such as Alumium etc.

use high flash point coolant.

Summary of Contents for FU 321M

Page 32: ...OPERATING AND MAINTENANCE MANUAL FU 321M 29 ELECTRIC EQUIPMENT DETAILS...

Page 33: ...OPERATING AND MAINTENANCE MANUAL FU 321M 30 ELECTRIC ARRANGEMENT...

Page 34: ...OPERATING AND MAINTENANCE MANUAL FU 321M 31 BUTTON ARRANGEMENT FRONT PANEL 10...

Page 35: ...OPERATING AND MAINTENANCE MANUAL FU 321M 32 BUTTON ARRANGEMENT SIDE PANEL WARNING...

Page 39: ...OPERATING AND MAINTENANCE MANUAL FU 321M 36 Fig 3a 45 41 46 51 48 43 52 44 42 53 49 50 47...

Page 40: ...OPERATING AND MAINTENANCE MANUAL FU 321M 37 SEMI AUTOMATIC CYCLE...

Page 43: ...OPERATING AND MAINTENANCE MANUAL FU 321M 40 Fig 6 1 2...

Page 46: ...OPERATING AND MAINTENANCE MANUAL FU 321M 43 Fig 10 4 3 2 1...

Page 52: ...OPERATING AND MAINTENANCE MANUAL FU 321M 49 Fig 16 3 ELECTRIC CIRCUIT DIAGRAM...

Page 57: ...OPERATING AND MAINTENANCE MANUAL FU 321M 54 Fig 18 3 4 1 2 1 1 1 1 1 1 7 5 6 1 1...

Page 60: ...OPERATING AND MAINTENANCE MANUAL FU 321M 57 Fig 21 OPERATOR S WORKING POSITION ON THE MACHINE...

Page 62: ...OPERATING AND MAINTENANCE MANUAL FU 321M 59 Fig 23 MARKING ON THE PACKING 2170 2370...

Page 63: ...OPERATING AND MAINTENANCE MANUAL FU 321M 60 Fig 24 DIGITAL READOUT SYSTEM...