OPERATING AND MAINTENANCE MANUAL FU 321M

19

DESCRIPTION OF THE MAIN MACHINE UNITS

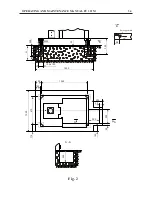

The disposition of machine main units is shown in Fig.25.

BODY, YOKE AND BRACKETS

The Body of the machine is a basic part where all units and mechanisms are

assembled upon. The Body is fixed on a cast iron base which is used as a coolant

tank as well.

The Spindle gear box electric motor is mounted in the back recess of the Body

and the electric cabinet is fitted in the right recess of the machine Body.

The Yoke slides along the horizontal guideways. It is fixed on the Body by nuts

10 / Fig.3 /. The tightening force exerted on the spanner should be about

500-600 N. One or two brackets (depending on the type of work done) in which

the bearings of the cutter arbors are positioned, are placed in the yoke front end.

The bracket holes are machined on spot individually for each machine, so the

brackets cannot be used on other milling machines. They are tightened to the Yoke

by means of nuts 11 / Fig.3 /.

The radial backlash of bearing 7 / Fig.1, A-A / is adjusted by nut 8. The good

functioning of the bearings 7 depends on the proper backlash adjustment and the

sufficient lubrication. Non-observance of any of these conditions will cause seizure

or premature wear out and breakage of the bearing 7.

SPINDLE GEAR BOX

The gear box is mounted in the machine body and is driven by an electric motor

through V-belts. The gear box ensures 18 spindle speeds / Fig.12 /.

The radial backlash of the spindle bearing is adjusted by the manufacturer and is

within 0.004-0.005 mm. In case the bearing should be replaced by a new one, the

radial backlash is adjusted with the help of nut 2 and ring 1 / Fig.4 /.

Belts 4 / Fig.10 / are tensioned as follows: open cover 22 / Fig.3 /, unscrew the

nuts 3 / Fig.10 / and by bolts 2 / Fig.10 / the rocker 1 / Fig.10 / is inclined till

tensioning of belts is performed. Then the bolts 2 are locked by nuts 3.

Belt tensioning is checked as it is pressed in the middle with force 100 to 150 N.

The feed should be 20-25 mm.

CAUTION:

Maximum allowed spindle torque should be 600 Nm.

Summary of Contents for FU 321M

Page 32: ...OPERATING AND MAINTENANCE MANUAL FU 321M 29 ELECTRIC EQUIPMENT DETAILS...

Page 33: ...OPERATING AND MAINTENANCE MANUAL FU 321M 30 ELECTRIC ARRANGEMENT...

Page 34: ...OPERATING AND MAINTENANCE MANUAL FU 321M 31 BUTTON ARRANGEMENT FRONT PANEL 10...

Page 35: ...OPERATING AND MAINTENANCE MANUAL FU 321M 32 BUTTON ARRANGEMENT SIDE PANEL WARNING...

Page 39: ...OPERATING AND MAINTENANCE MANUAL FU 321M 36 Fig 3a 45 41 46 51 48 43 52 44 42 53 49 50 47...

Page 40: ...OPERATING AND MAINTENANCE MANUAL FU 321M 37 SEMI AUTOMATIC CYCLE...

Page 43: ...OPERATING AND MAINTENANCE MANUAL FU 321M 40 Fig 6 1 2...

Page 46: ...OPERATING AND MAINTENANCE MANUAL FU 321M 43 Fig 10 4 3 2 1...

Page 52: ...OPERATING AND MAINTENANCE MANUAL FU 321M 49 Fig 16 3 ELECTRIC CIRCUIT DIAGRAM...

Page 57: ...OPERATING AND MAINTENANCE MANUAL FU 321M 54 Fig 18 3 4 1 2 1 1 1 1 1 1 7 5 6 1 1...

Page 60: ...OPERATING AND MAINTENANCE MANUAL FU 321M 57 Fig 21 OPERATOR S WORKING POSITION ON THE MACHINE...

Page 62: ...OPERATING AND MAINTENANCE MANUAL FU 321M 59 Fig 23 MARKING ON THE PACKING 2170 2370...

Page 63: ...OPERATING AND MAINTENANCE MANUAL FU 321M 60 Fig 24 DIGITAL READOUT SYSTEM...