507029-03

Page 54 of 68

Issue 1622

5.

If second-stage heat is required, the thermostat

second stage heat contacts close and send a signal

to the integrated control

.

The integrated control either

increases the fi

r

i

ng rate to 70 percent (if the current rate

is at or below 60 percent) or increases the firing rate by

10 percent (if the current rate is above 60 percent)

.

If

the call for heat continues 5 minutes beyond this initial

upstage

,

the rate will be

i

ncreased by 10 percent every

5 minutes until the call for heat

i

s satisfied or the furnace

reaches 100 percent rate

.

As the firing rate increases

,

the

i

ndoor blowe

r

motor is adjusted to a speed which

is appropriate for the target rate

.

6. If second-stage heat demand is satisfi

ed

,

but first stage

is still present

,

the furnace will continue to operate at

the present firing rate until the heat cyc

l

e ends

.

7. When the demand for first and second stage heat

is satisfied

,

the gas valve is de-energized and the

fieldselected indoor blower off delay begins

.

The

combustion air inducer begins a 20 second post-purge

per

i

od

.

8. When the combustion air post purge period is complete,

the inducer is de-energized

.

The indoor blower is de-

energized at the end of the off delay

.

Applications Using A Single-Stage Thermostat

C - Heating Sequence — Control Thermostat Selection

DIP switch in “Single Stage” Position

1. On a call for heat

,

thermostat first stage contacts

close sending a signal to the integrated control

.

The

integrated control runs a self-diagnostic program and

checks high temperature limit switches for normally

closed contacts and pressure switches for normally

open contacts

.

The combustion air

i

nducer is energized

at the ignition speed

,

which

i

s approximately the same

as the inducer speed at 70 percent firing rate

.

2.

Once the control receives a signal that the low fire

pressure switch has closed

,

the combustion air inducer

begins a 15 second prepurge at the

i

gnition speed

.

3. After the prepurge is complete

,

a 20 second

i

nitial ignitor

warm up period begins. The combustion air inducer

continues to operate at the ign

i

tion speed

.

4. After the 20 second warm up period has ended

,

the gas

valve is energized and ignition occurs

,

which initiates a

10 second ignition stabilization delay

.

At the same time

,

the control module sends a signal to begin an indoor

blower 30 second

ON

delay

.

When the delay ends

,

the indoor blower motor is energized at a speed which

is appropr

i

ate for the firing rate

.

After the 10 second

ignition stabilization delay expires

,

the inducer speed is

adjusted to 40 percent speed. The integrated control

also initiates a second-stage on delay (factory set at 7

m

i

nutes

;

adjustable to 12 minutes)

.

5. If the heat

i

ng demand continues beyond the secondstage

on delay

,

the integrated control energizes the combustion

air inducer at 70 percent speed

.

The indoor blower

motor is adjusted to a speed which matches the target

rate

.

A fixed

,

10 minute third stage on delay is initiated

.

6. If the heating demand continues beyond the thirdstage

on delay

,

the integrated control energ

i

zes the inducer

at high speed

.

The indoor blower motor

i

s adjusted to

a speed which is appropriate for the target rate

.

7. When the thermostat heating demand is satisfied

,

the gas valve is de-energized and the combustion

air inducer begins a 20 second post purge

.

The field

selected

i

ndoor blower off delay begins

.

8. When the combustion air post purge period is complete

,

the inducer is de-energized

.

The indoor blower is de-

energized at the end of the off delay

.

Summary of Contents for A97DSMV

Page 3: ...507029 03 Page 3 of 68 Issue 1622 A97DSMV Exploded View Figure 1...

Page 13: ...507029 03 Page 13 of 68 Issue 1622 OUTDOOR TERMINATION KITS USAGE Table 3...

Page 24: ...507029 03 Page 24 of 68 Issue 1622 Figure 29...

Page 27: ...507029 03 Page 27 of 68 Issue 1622 Figure 36 Trap Drain Assembly Using 1 2 PVC or 3 4 PVC...

Page 33: ...507029 03 Page 33 of 68 Issue 1622 Figure 43 Typical A97DSMV Wiring Diagram...

Page 34: ...507029 03 Page 34 of 68 Issue 1622 Figure 45...

Page 35: ...507029 03 Page 35 of 68 Issue 1622 Figure 46...

Page 36: ...507029 03 Page 36 of 68 Issue 1622 Figure 47 Integrated Control...

Page 40: ...507029 03 Page 40 of 68 Issue 1622 Low Voltage Field Wiring Table 14 Single Stage 2 Stage...

Page 44: ...507029 03 Page 44 of 68 Issue 1622 BLOWER DATA...

Page 57: ...507029 03 Page 57 of 68 Issue 1622...

Page 58: ...507029 03 Page 58 of 68 Issue 1622...

Page 59: ...507029 03 Page 59 of 68 Issue 1622...

Page 60: ...507029 03 Page 60 of 68 Issue 1622 Configuring Unit Size Codes...

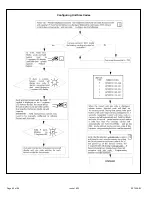

Page 61: ...507029 03 Page 61 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation...

Page 62: ...507029 03 Page 62 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Page 63: ...507029 03 Page 63 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Page 64: ...507029 03 Page 64 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Page 65: ...507029 03 Page 65 of 68 Issue 1622 Troubleshooting Cooling Sequence of Operation...

Page 66: ...507029 03 Page 66 of 68 Issue 1622 Troubleshooting Continuous Fan Sequence of Operation...