MANUALE D’USO ROUTE - rev. 2 - 10/01

pag. 5/15

The maximum continuous working temperature referred to water depends on the choice of materials

(specified on the identification plate):

80 °C (176 °F)

execution WR

110 °C (230 °F)

execution GF

The ambient temperature interval is related to the choice of materials (specified on the identification plate):

0 - +40°C (14

÷

104 °F)

execution WR

-20 - +40°C (-4

÷

104 °F)

execution GF

The maximum pressure the pump may be subjected to is 1.5 times the head value developed with the outlet

closed.

The vapour pressure value of the liquid to be pumped must exceed (by at least 1m w.c) to the difference

between the absolute total head (suction side pressure added to the positive suction head, or subtracted by

the suction lift) and the pressure drops in the suction side piping (including the inlet NPSHr drops shown on

the specific tables).

The pump does not include any non return valve nor any liquid flow control or motor stop device.

5 OPERATING

PRINCIPLE

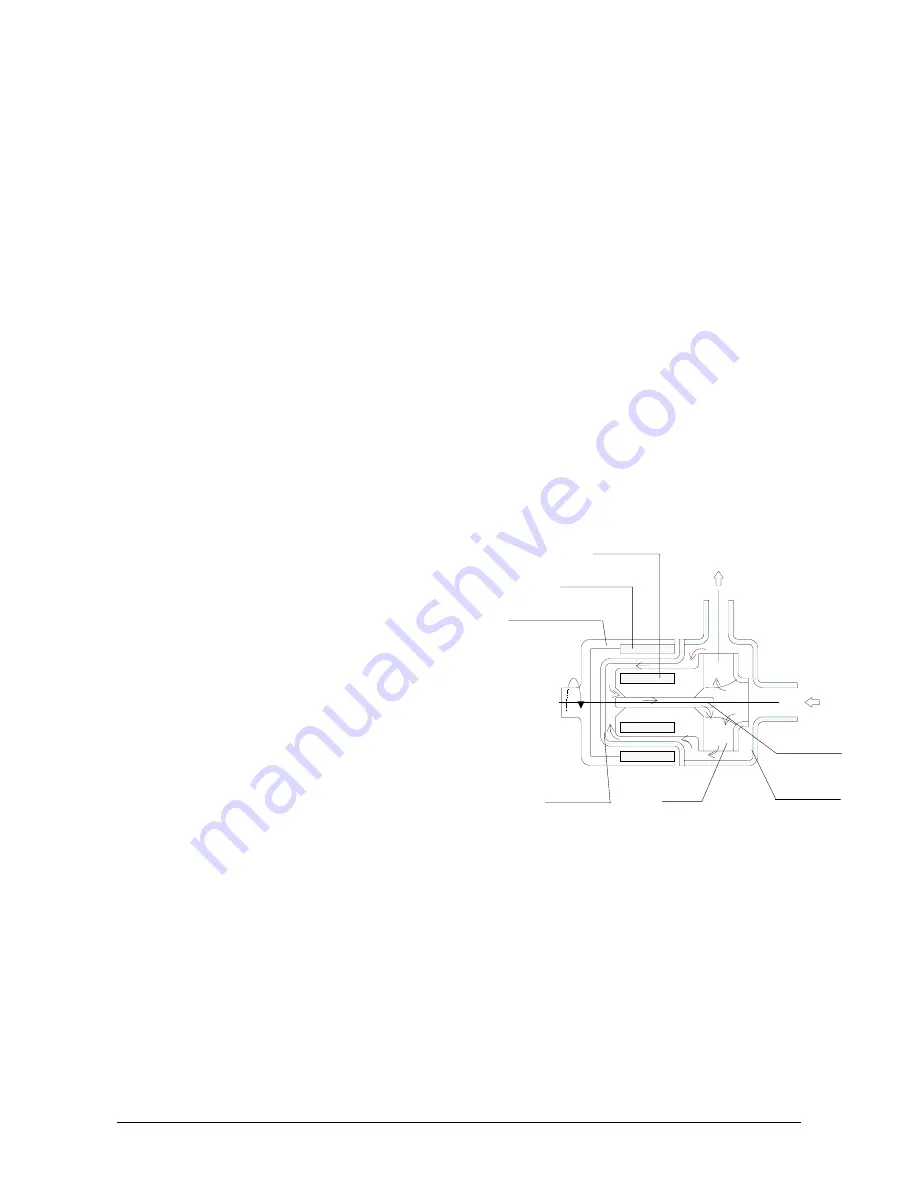

HYDRAULICALLY alike to all centrifugal pumps, it is equipped with a blade-type impeller rotating within a

fixed housing. It has a tangential outlet (or radial with an internal deflector) and, by creating a depression in

the center, it allows the liquid to flow from the central suction side. Then, flowing through the impeller's

blades, the fluid acquires energy and is conveyed towards the outlet.

MECHANICALLY different from the traditional

centrifugal pumps in the impeller motion drive thanks

to the magnetic field created between the primary

outer magnet and the inner magnet (not visible

because housed inside the impeller hub). The

magnetic field crosses the plastic parts and the liquid,

and firmly couples the two magnet assemblies. When

the motor causes the outer magnet to rotate together

with its housing, the inner magnet assembly is

dragged at the same speed. As a result the impeller,

which is integral to it, is maintained in rotation.

The SHAFT, totally within the housing, is not involved

in the transmission of rotary motion; its only function is

to act as a centering guide and support for the

impeller. To this end the components are designed so

that a spontaneous cooling circuit (due to a simple

effect of pressure) is established to cool the surfaces

subject to friction. Periodic inspections prevent the

build-up of sediments between the shafts and the

guide bushes significantly lengthening their working

life.

motor side

outer magnet housing

outer magnet

inner magnet

outlet

inlet

pump shaft

impeller

rear casing

volute casing