7.2.1 Volt Setting & Measurement Calibration

This item is for calibrating the voltage setting and measurement. Make sure to disconnect the

Resistive load before starting calibration.

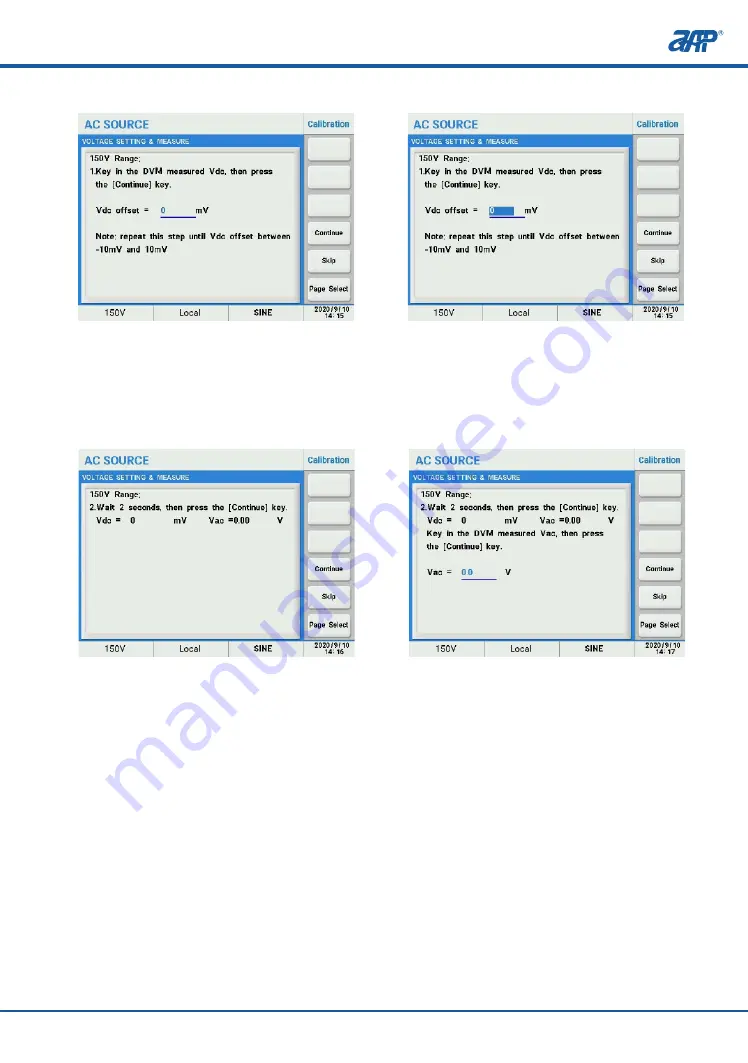

1. Once the password has been entered press the soft key to the right of ‘Volt Setting & Measure’.

2. You will enter into the 150V Range voltage calibration. Make sure there is NO Load at the

output. Then press the ‘Continue’ soft key for the next step.

3. Highlight the value field and enter the DVM DC voltage reading and repeat this step until

the DVM reading is between -10mV and 10mV.

Calibration

94

PROFESSIONAL INNOVATIVE BRANDING SERVICE

4. Wait 2 seconds then press the ‘Continue’ key.

5. Highlight the value field and enter the DVM AC voltage reading then press the ‘Continue’

soft key for the next step.

Follow the on-screen prompts to complete calibration the 150V AC range. Both AC & DC output

and AC & DC measurements are calibrated.

Once completed, repeat the same process for the 300V AC range.

7.2.2 Current Measurement Calibration

This menu is for calibration of the power source’s current measurement functions. The power

source uses up to four measurement ranges depending on models. Each range has two

calibration coefficients.

Follow the on-screen prompts to complete the complete calibration sequence for all ranges

and coefficients.

Calibration

95

PROFESSIONAL INNOVATIVE BRANDING SERVICE

Summary of Contents for SP-300 Series

Page 2: ......

Page 90: ...Main page 88 Master slave Mode Operation PROFESSIONAL INNOVATIVE BRANDING SERVICE...

Page 129: ......

Page 130: ......

Page 131: ......