PCH cold storage generator module

APEN GROUP SPA reserves the right to contribute the necessary modifications to the documentation or documentation

6

cod. HG0130.05GB ed.B-2104

PCH

7

cod. HG0130.05GB ed.B-2104

PCH

HG0130.00 A

002

3.

TECHNICAL FEATURES

The modulating condensing warm air heaters of PCH series

have been designed to be installed in air handling and roof-top

units as heating units.

The premixing and modulating technology allows the heater to

achieve efficiency of up to 109% of the L.C.V. (lower calorific

value). The unit can be used on all machines requiring air to

be heated during their operation (such as dryers, ventilation

systems etc.).

The unit can operate independently. To start up the unit, simply

connect it to the mains power supply and to the gas mains.

The heat output of modules ranges from 5 to 97 kW. For greater

output levels, multiple PCH modules must be combined. They

can be assembled in parallel to reach great heat output (up to

400 kW).

The units can be controlled in three ways:

• proportionally, with a 0-10 Vdc external control;

• with ON-OFF control;

• with cascaded operation, when more units are installed.

The PCH module can be installed with the front panel, supplied

as an accessory, positioned directly on the outside, with no

additional guard.

The air is heated through its passage on combustion chamber

and exchanger pipe surfaces.

The heat exchanger complies with the construction requirements

for equipment where combustion gases produce condensate.

The combustion chamber and the surfaces in contact with

condensation (such as the pipe bundle and exhaust hood),

are made of AISI 441, in order to provide high resistance to

condensation.

The following table shows the conversion of stainless steels used:

USA-AIS

EN-No.

COMPOSITION

AISI 430

1.4016

X6 Cr17

AISI 441

1.4509

X2 CrTiNb 18

The innovative design and large surface of the combustion

chamber and heat exchanger pipes ensure optimum efficiency

and durability.

The burner is made entirely of stainless steel with special

mechanical solutions to ensure optimal reliability and

performance levels, as well as high thermal and mechanical

resistance.

The control located inside the burner housing allows the service

centre to check and view the working phases and identify any

faults that may have occurred.

The PCH heater has a modulating mode of operation; the thermal

output and, therefore, the heat output (fuel consumption) vary

according to the heat demand. When the heat demand from the

environment reduces, the heater uses less gas and increases

its efficiency - up to 109% (a Net caloric value).

Inherent Safety

The efficiency increase at minimum power is achieved by using

a sophisticated air/gas mixing technique and by regulating at

the same time the combustion air flow and the fuel gas flow.

This technology increases the heater safety as the gas valve

supplies the fuel according to the air flow. Unlike atmospheric

burners, the CO

2

content remains constant throughout the heater

operating range, allowing the heater to increase its efficiency

when the heat output reduces.

If there is no combustion air, the valve will not supply gas; if

the combustion air flow reduces, the valve will automatically

reduce the gas flow yet will keep its combustion parameters

at optimal levels.

Low emissions

The premixed burner, in combination with the air/gas valve,

ensures "clean" efficient combustion having very low emissions.

Control panel

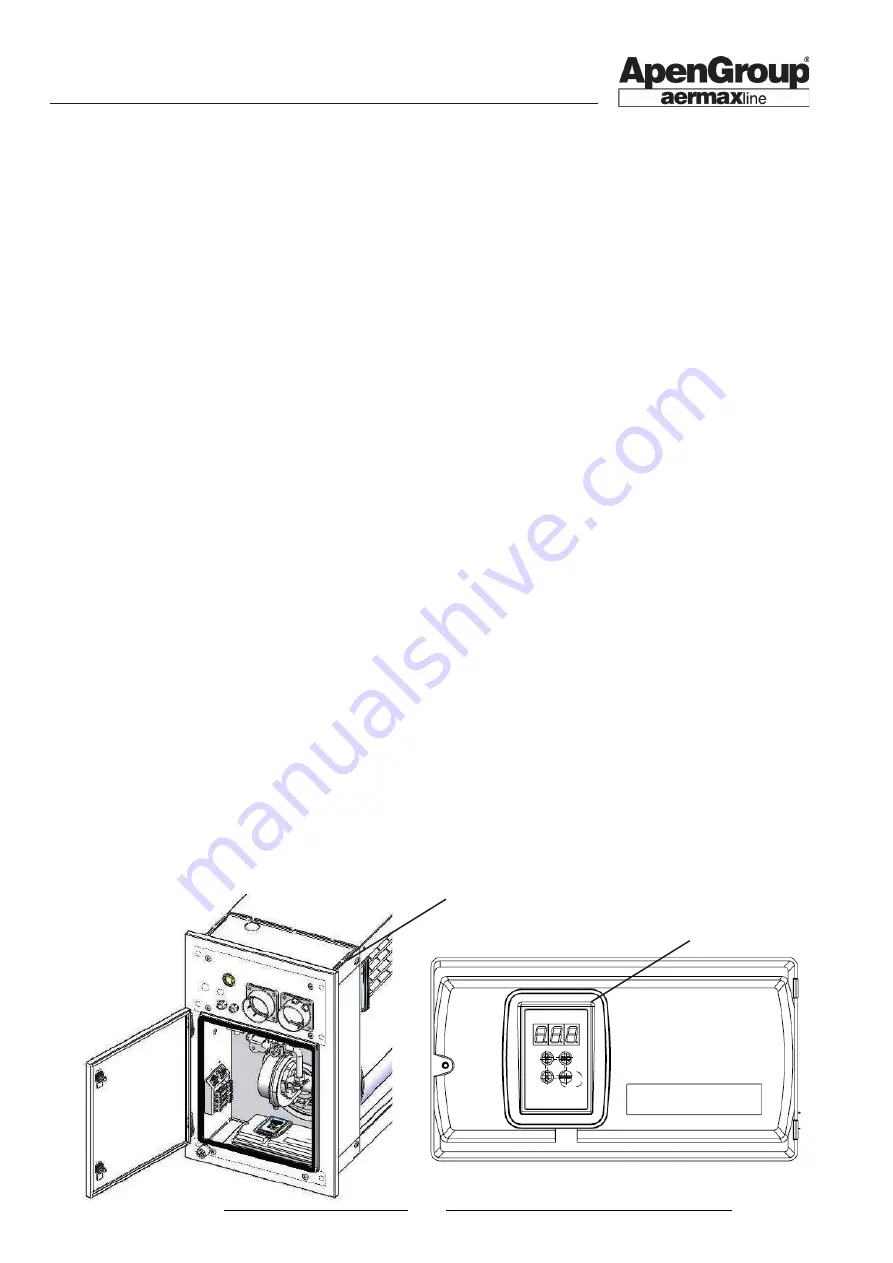

Example of installation of a PCH heater with door

PCH series display