Anthony Lifgtates, Inc.

42

MRT Models

www.anthonyliftgates.com

800-482-0003

7.2 Maintenance And Troubleshooting

Procedures

7.2.1 Check Lowering Valve Cartridge And Coil

1. Place the platform on the ground in the open position.

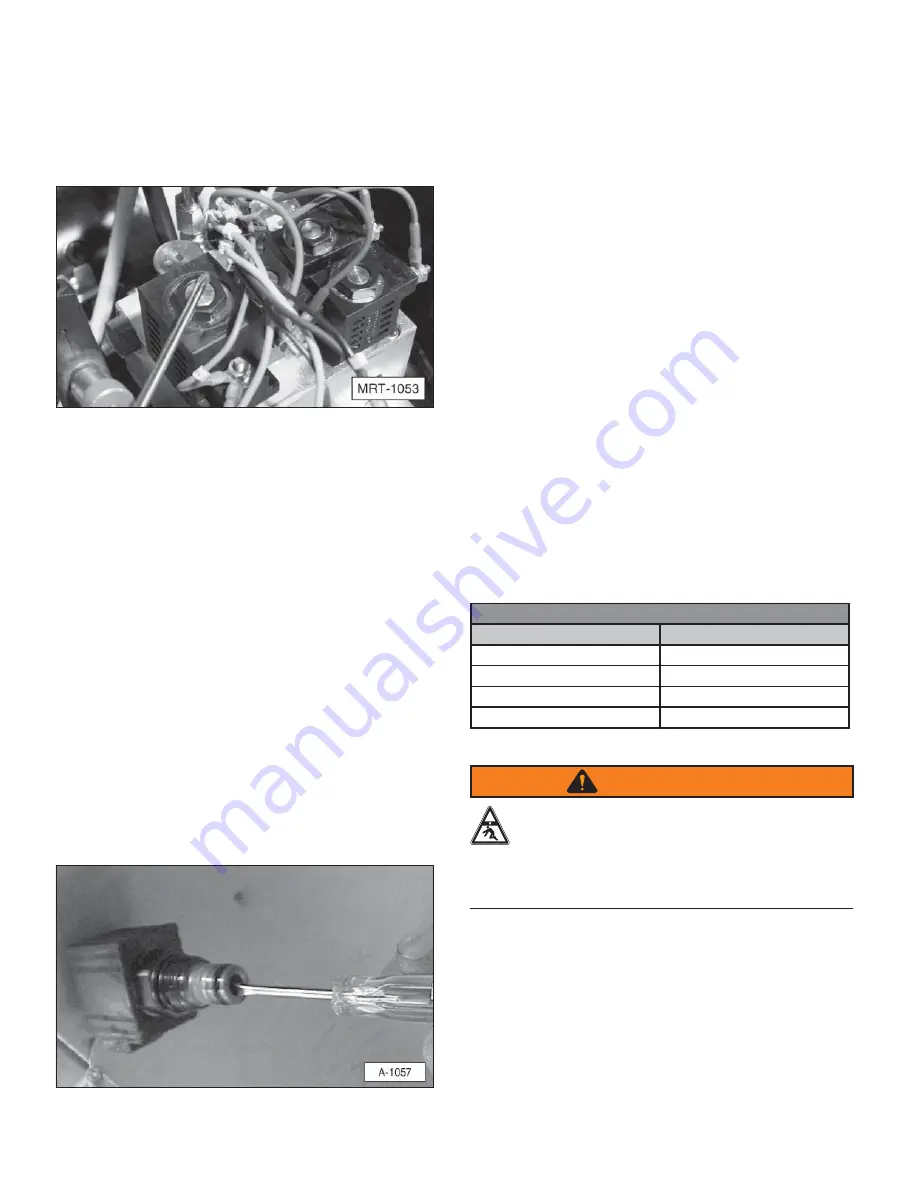

2. Place a steel screwdriver over the top of the lowering

valve cartridge coil.

3. Momentarily activate the control switch in the

DOWN position. The screwdriver should be attracted

to the magnetic field created by the coil.

4. If there is no magnetism, determine if there is power

from the control switch to the coil. If there is no

power, determine if the switch is bad or if the problem

is in the wire from the switch to the coil. If there

is power to the coil, but it has no magnetism, then

the coil is bad and should be replaced. If the coil is

good, check the lowering valve cartridge for proper

operation.

5. Remove the coil from the lowering valve cartridge

assembly.

6. Remove the lowering valve cartridge from the pump

body.

7. Clean the lowering valve cartridge and blow it dry with

compressed air (not greater than 30 psi). Also, blow

out the pump body.

8. Use a small screwdriver and carefully press on the

poppet inside the lowering valve cartridge. The

poppet is spring loaded and should move when it

is pressed. If the poppet does not move, then the

lowering valve cartridge should be replaced.

7.2.2 Inspect Cylinder Piston Seals

Inspect the cylinder piston rod seals for drifting, caused by

seal leakage.

1. Remove the breather hose, if equipped.

2. Raise the platform all the way up and hold the switch

in the “ON” position while checking for oil coming out

of the breather port to the cylinder.

3. If a continuous flow of oil comes out of this port,

while the platform is all the way up and the switch is

held “ON”, then the piston seals are leaking and the

cylinder should be replaced.

7.2.3 Checking System Pressure

Power down models have two relief valve settings; one

for raising the platform (power up) and one for lowering

the platform (power down).

To check the “power up” pressure setting:

1. Place the liftgate on the ground and remove the

pressure hose from the power up port of the pump.

2. Install a tee (customer supplied) into the power up

port.

3. Connect a pressure gauge and reconnect the

hydraulic hose.

The pressure gauge must be rated above the maximum

pressure of the liftgate. For example, use a 4000 psi

pressure gauge on a 3000 psi maximum capacity liftgate.

Low Pressure Threshold Chart

Model

Low Pressure Threshold

MRT-3500

1500 psi

MRT-4500

1700 psi

MRT-5500

2000 psi

MRT-6500

2400 psi

WARNING

CRUSH HAZARD

Do not stand or work in the platform’s work

area while operating the liftgate. Place the

pressure gauge so it can be read while operating the

liftgate from a safe location. Serious injury or death

could result if this action is not followed.

4. Raise the liftgate and check the pressure.

5. If the appropriate pressure cannot be reached,

replace the pump.

6. Check the power down relief valve pressure in the

same way as the gravity down system by installing a

tee and gauge.

7. The power-down pressure should not exceed 500 psi.