MRT Models

27

Anthony Lifgtates, Inc.

800-482-0003

www.anthonyliftgates.com

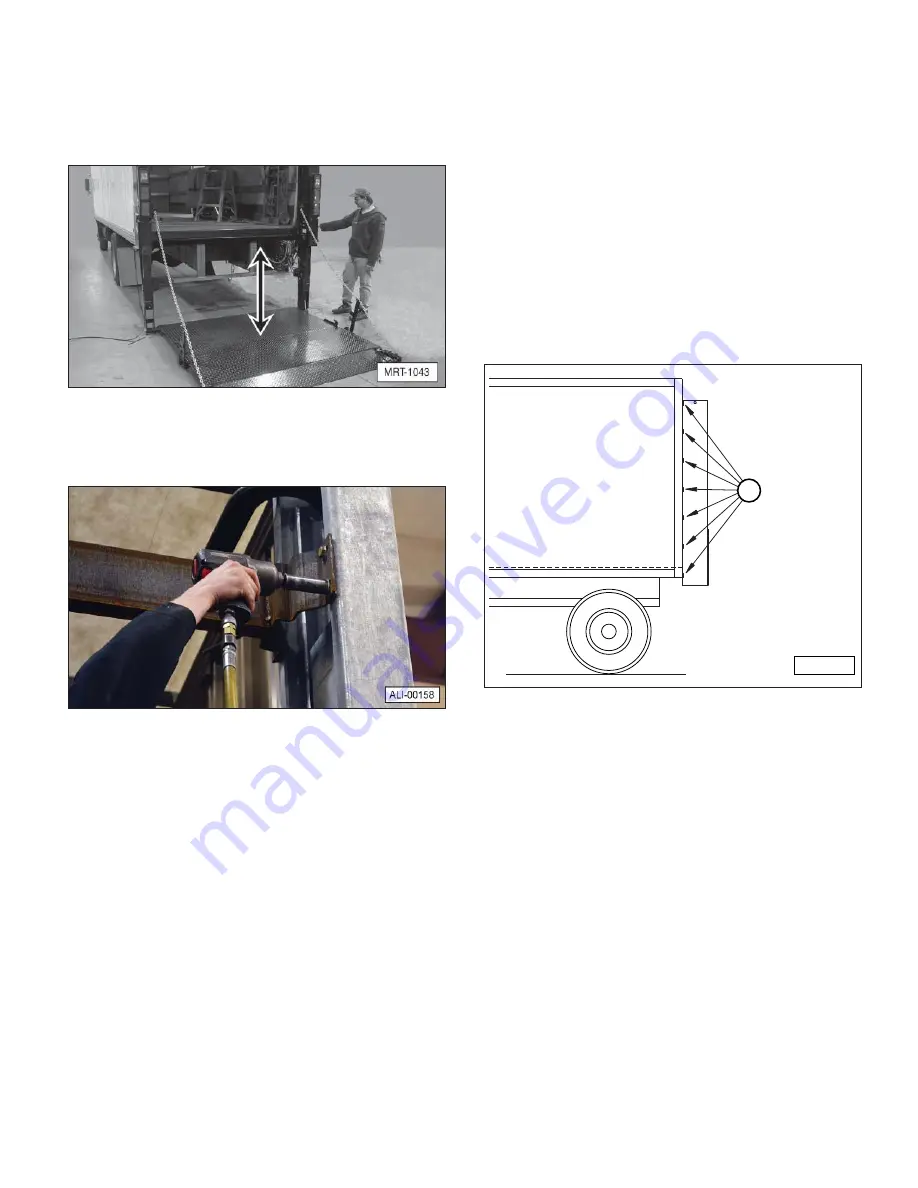

6. Raise and lower the platform to make sure it operates

without binding. Air introduced into the system during

installation will work itself out after several cycles of

normal operaton. To bleed air out of the cylinders,

refer to “4.12 Air Bleeding Procedure For MRT

Liftgates (Gravity Down Models ONLY!)” on page

30.

7. If the liftgate has been successfully operated through

its cycle, remove and discard the upper shipping

support.

4.8.6 Complete The Final Welding

1. Thoroughly check the position of the liftgate assembly

before starting the final welding.

a. The liftgate must be centered on the chassis or

trailer.

b. The crossmember must be flush with the floor.

c. Both columns must be tight against the rear frame.

d. The columns must be square with the vehicle body

and parallel to each other.

If any of these items is not correct, reposition the liftgate.

2. Weld the liftgate columns to the rear frame of the

chassis or trailer using seven, equally spaced 3/16”

wide by 2” long welds (A) down both sides (inside and

outside) of each column (28 total welds).

A

MRT-1006

Tip: Do not over weld the outside of the columns,

because too much heat can damage the hoses and

wires inside the columns.