Edition 3

Rev G

Section 3

3-43

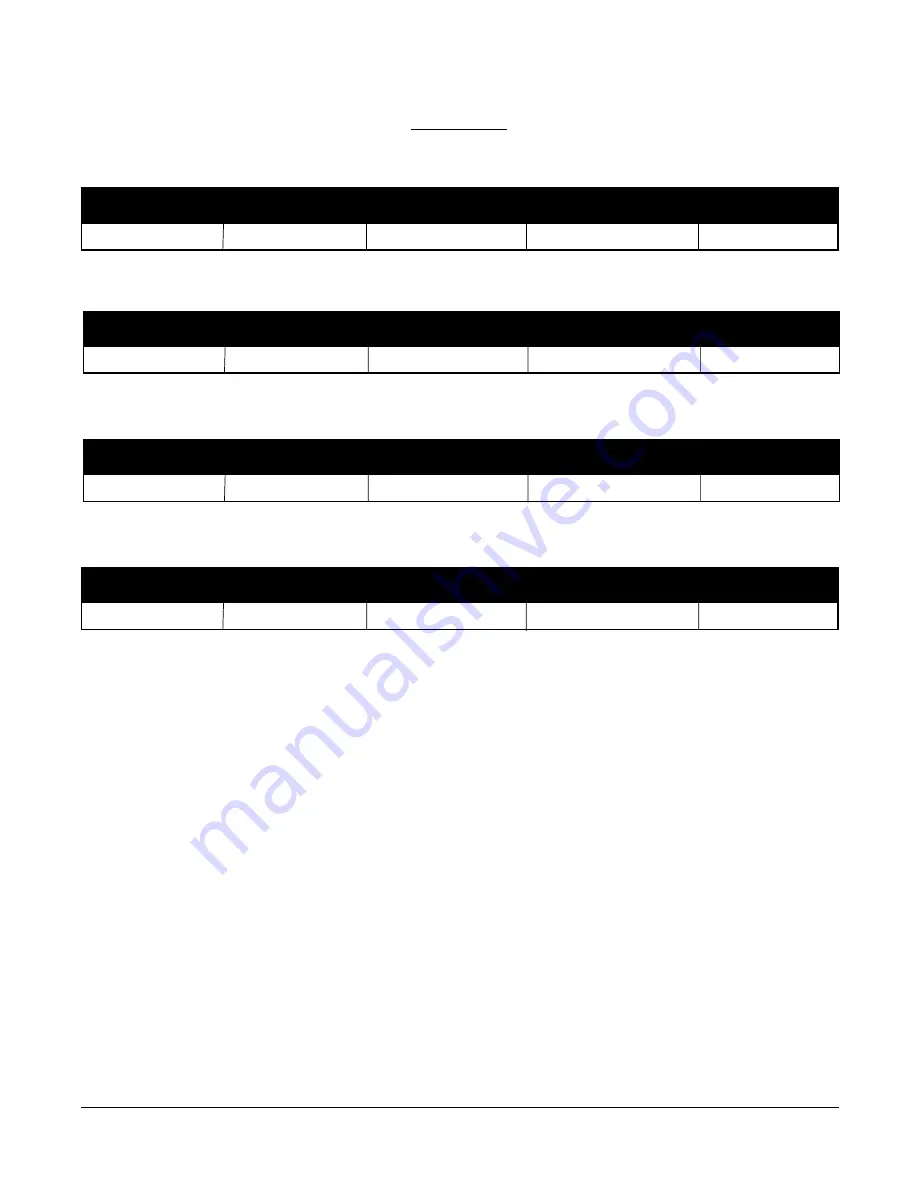

Software Reference/Record Sheet

Configuration

ALARM SETTINGS

PV 1

ALM 1 (A11)

ALM 2 (A12)

ALM 3 (A13)

ALM 4 (A14)

SETPOINT

PV 2

ALM 1

ALM 2

ALM 3

ALM 4

PV 3

ALM 1

ALM 2

ALM 3

ALM 4

PV 4

ALM 1

ALM 2

ALM 3

ALM 4

PV 2

ALM 1 (A21)

ALM 2 (A22)

ALM 3 (A23)

ALM 4 (A24)

SETPOINT

PV 3

ALM 1 (A31)

ALM 2 (A32)

ALM 3 (A33)

ALM 4 (A34)

SETPOINT

PV 4

ALM 1 (A41)

ALM 2 (A42)

ALM 3 (A43)

ALM 4 (A44)

SETPOINT

Summary of Contents for AV-9000

Page 2: ......

Page 4: ......

Page 22: ......

Page 290: ...Appendix A Edition 3 Rev G A 2 FIGURE A 2 MOTHER BOARD J5 J6 J4 J7 J1 J3...

Page 293: ...Edition 3 Rev G Appendix A A 5 FIGURE A 5 MOTOR DRIVER BOARD J4B J5 J6 J1 J7 J4A J3 J2...

Page 295: ...Edition 3 Rev G Appendix A A 7 FIGURE A 7 TRANSMITTER POWER SUPPLY BOARD J3 TB2 TB1 TB3 TB4...