INSTALLATION INSTRUCTIONS

TYPE 21 SHAFT SEAL

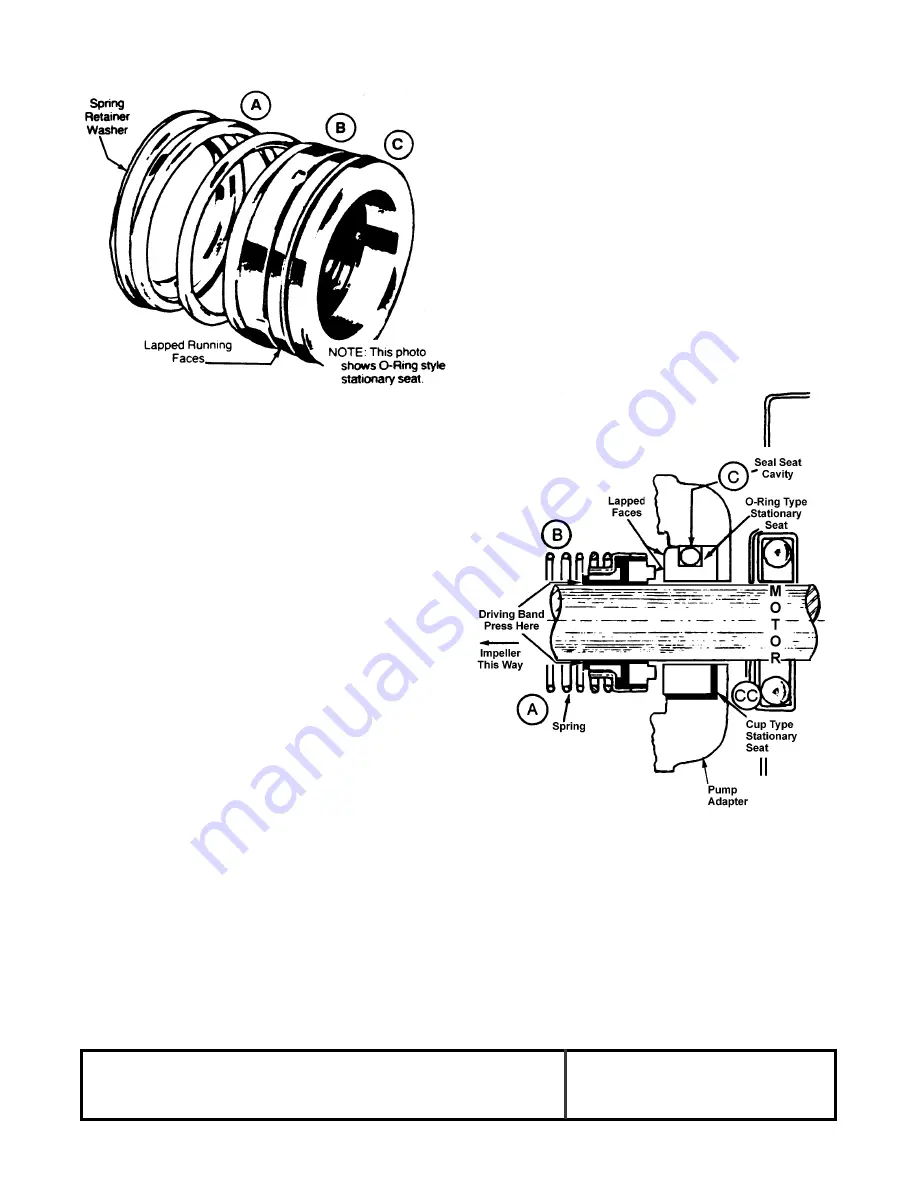

The seal assembly consists of these components:

A

SPRING

B

ROTARY SEAL HEAD

C

STATIONARY SEAT - May

have an O-ring groove in seat (C)

or a rubber cup seat (CC).

CAUTION:

This seal is a precision product and should

be handled accordingly. Be especically careful of the

lapped sealing surface of the rotary washer and

stationary seat.

THE SEAL IS SUPPLIED WITH

A PACKET OF LUBRICANT.

LAPPED RUNNING FACES

The lapped running surfaces of the rotary seal head

and stationary seat must be treated with care. KEEP

CLEAN. DO NOT SCRATCH. Use a clean, soft cloth

during installation. Protect the faces. Install both the

seat and rotary square to the shaft. Check the

stationary seat installation from behind the seal cavity

for squareness.

STATIONARY SEAT INSTALLATION (C)

Clean the seal seat cavity of the adapter and lubricate.

Lubricate the seat O-ring or cup and press the

stationary seat in seal cavity of the adapter squarely

and evenly using an arbor press and the cardboard disc

supplied with the seal. Be careful not to scratch or

touch the lapped surface of stationary seat.

Inspect the face of the stationary seat to be certain

there is no dirt on face. If there is any dirt or fingerprints

on the face, wipe it off carefully with a soft cloth.

ROTARY SEAL HEAD INSTALLATION (B)

Clean, polish and lubricate the shaft (or shaft sleeve).

Check lapped faces on the stationary seat and rotary

seal head. Be certain no dirt is on either face.

Lubricate lightly.

Slide the rotary seal head on the shaft with the carbon

rotating ring facing the stationary seat. Press the drive

band until the head seats firmly against the seat. Install

spring (and spring retainer washer if used). Install

impeller which will compress the spring to proper length

assuring correct pressure on the lapped faces.

CAUTION:

Never operate the lapped running faces

dry. The liquid being handled ensures proper

lubrication.

In some cases a short period of operation is required

to clear up slight leakage.

NOTE: The lubricant supplied with the seal is the

only approved lubricant. DO NOT USE OTHER

LUBRICATING LIQUIDS!

61.000.172B

JANUARY 2000

SCOT

HOME OFFICE

• Cedarburg, WI 53012

• P.O. Box 286

• 262-377-7000

•

FAX 262-377-7330

FACTORY BRANCHES

• Irvine, CA 92614

• 1881 Kettering

• 949-756-8076

•

FAX 949-756-9480

• Ft. Lauderdale, FL 33315

• 77 SW 20th Street

• 954-524-6776

•

FAX 954-764-3361

SCOT

DIVISION OF

ARDOX CORP.

Replaces March 1990

20 of 34

Summary of Contents for ICS-TCP Series

Page 11: ...11 of 34 ...

Page 12: ...12 of 34 ...

Page 13: ...13 of 34 ...

Page 14: ...14 of 34 ...

Page 15: ...15 of 34 ...

Page 16: ...16 of 34 ...

Page 17: ...17 of 34 ...

Page 18: ...18 of 34 ...

Page 19: ...19 of 34 ...

Page 22: ...Amiad USA INC Level I Filter Controller UL 508A Standard 22 of 34 ...

Page 32: ...Page 11 Rev 091014 Operating and Maintenance Manual Page 11 32 of 34 ...