23

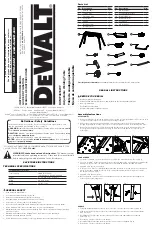

Q. Install electrical system

Connect the power source on the data plate of power unit.

Note: 1. For the safety of operators, the power wiring must contact the floor well.

2. Pay attention to the direction of rotations when using three phase motors.

Single phase motor (See Fig. 34).

1.

Connecting the two power supply lines (

Active

L

and

Neutral

wire

N

) to terminals of AC

contactor marked

6#, 2#

respectively.

2.

Connecting the power supply earth wire to

G

on the motor.

3.

Connecting the Limit Switch: Removing the wire of connecting terminal

4#

on

control button and terminal

1#

on AC contactor firstly

(See Fig. 35)

, then

connecting wire

10#

of the limit switch with terminal

4#

of the control button and

connecting wire

9#

with terminal

A1

on AC contactor respectively

(See Fig. 36)

.

Motor Connecting Diagram

Fig. 34

9#

Remove this wire

before connecting

the Limit Switch

10#

Fig. 35

Fig. 36

Summary of Contents for HS-12

Page 1: ...TWO POST LIFT Model HS 12 ...

Page 2: ......

Page 4: ...0 ...

Page 6: ...2 Arm Swings View For Model HS 12 Fig 2 ...

Page 12: ...8 D Install parts of extension columns See Fig 15 Fig 15 ...

Page 28: ...24 IV EXPLODED VIEW Model HS 12 Fig 37 Car in direction ...

Page 29: ...25 Main Cylinder Secondary Cylinder Fig 38 Fig 39 ...

Page 39: ...35 ...