16

18-CE15D1-1C-EN

Gas Valve Adjustment

Note:

The gas valve supplied with this unit has been calibrated

specifically for the Ultra Lo-NOx ignition system. Adjustment is

not typically necessary.

Manifold pressure adjustments are only recommended when there are

ignition light-off, flame stabilization, or tonal issues with the furnace.

To adjust the manifold pressure:

1.

Turn off all electrical power to the system.

2.

Attach a manifold pressure gauge with flexible tubing to the outlet

pressure boss marked "OUT P" on White- Rodgers gas valve

model 36J.

3.

Loosen (Do Not remove) the pressure tap test set screw one turn

with 3/32" hex wrench.

a.

The pressure tap adjustment kit (KIT07611) contains a 3/32"

hex wrench, a 5/16" hose and a connector and can be

ordered through Global Parts.

4.

Turn on system power and make a call for heating.

5.

To adjust the run manifold pressure, remove the high (HI)

adjustment regulator cover screw.

a.

To increase outlet pressure, turn the regulator adjust screw

clockwise.

b.

To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c.

Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d.

Replace and tighten the regulator cover screw securely.

6.

To adjust the light off manifold pressure, remove the low (LO)

adjustment regulator cover screw.

a.

To increase outlet pressure, turn the regulator adjust screw

clockwise.

b.

To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c.

Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d.

Replace and tighten the regulator cover screw securely.

7.

Cycle the furnace several times to verify regulator setting.

a.

Repeat steps 5-7 if needed.

8.

Turn off all electrical power to the system.

9.

Remove the manometer and flexible tubing and tighten the

pressure tap screw.

10. Using a leak detection solution or soap suds, check for leaks at the

pressure outlet boss and pressure tap test screw.

11. Turn on system power and check operation of the unit.

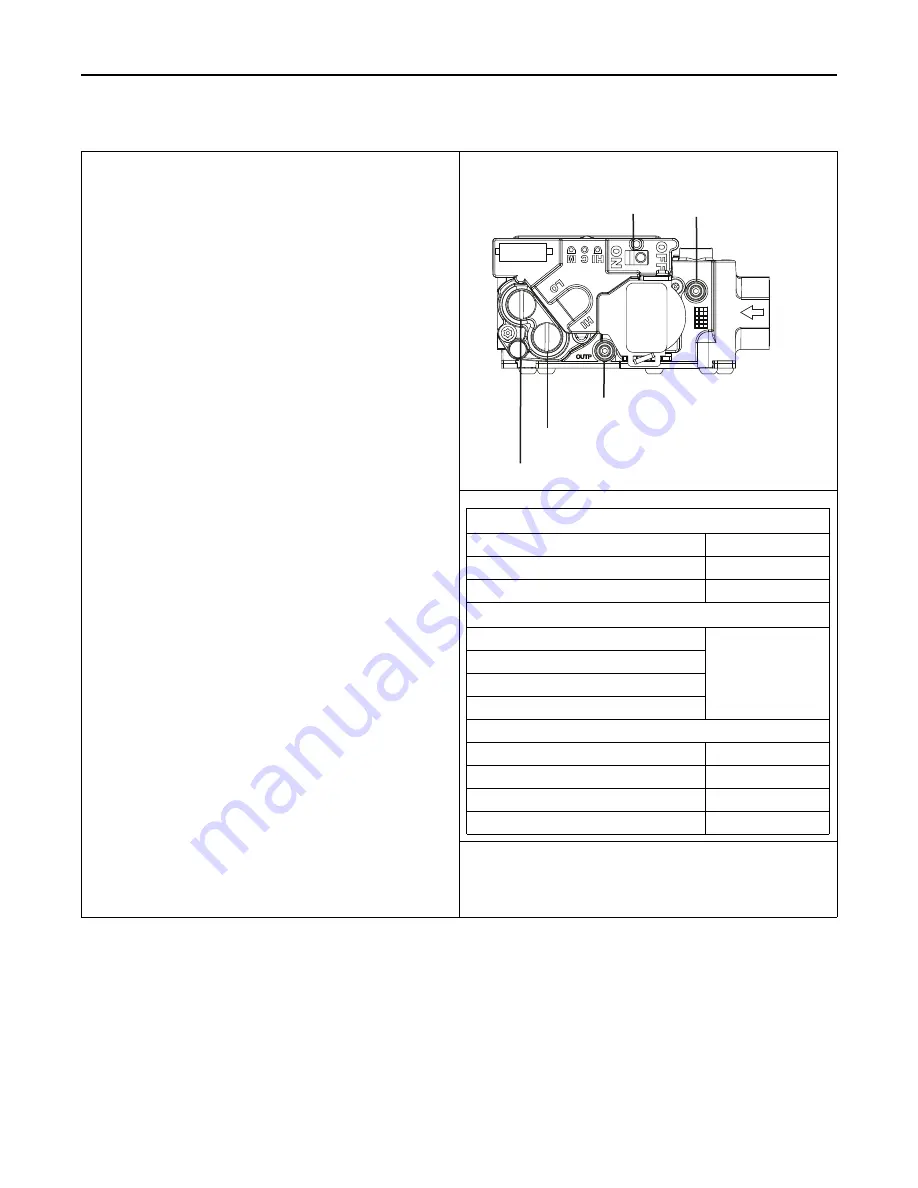

Outlet Pressure Boss

Run Stage (HI) Manifold Pressure Adjustment

Light Off (LO) Manifold Pressure Adjustment

Inlet Pressure

Boss

Gas Valve On/Off

Toggle Switch

White-Rodgers 36J

Maximum and Minimum INLET Pressure (inches w.c.)

Natural Gas

Maximum

13.8

Minimum

5

Recommended Fuel Manifold Settings (inches w.c.)

L8V1A040U3VS

2.1" Light-Off (LO) /

3.0" Run (HI)

L8V1A060U3VS

L8V1B080U4VS

L8V1C100U5VS

Orifice sizes for Natural Gas

L8V1A040U3VS

3.2 mm

L8V1A060U3VS

#23

L8V1B080U4VS

#15

L8V1C100U5VS

#11

Note:

Adjust RUN / (HI) manifold pressure to ~ 2.7" if high pitch

combustion sound develops.