44

18-CE15D1-1C-EN

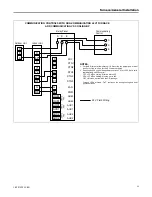

Sequence of Operation

E

EA

AC

C a

an

nd

d H

HU

UM

M T

Tiim

miin

ng

g

•

EAC relay closes approximately 5 seconds after the

blower starts.

•

EAC relay opens when the blower motor stops.

•

HUM relay closes on a gas heating call when the

blower motor starts and flame is sensed.

•

HUM relay opens when flame is no longer sensed,

i.e. thermostat is satisfied.

N

No

otte

e:: The EAC and HUM terminals are dry contacts, no

power output.

G

Ga

ass H

He

ea

attiin

ng

g

N

No

otte

e:: There are two main thermal limits on this unit.

Thermal Limit 1 is the primary limit for upflow

applications with right side return ducting.

Thermal Limit 2 is the primary limit for all other

applications.

1. R – W contacts close on the thermostat sending

24VAC to the W low voltage terminal of the IFC.

Technician should read 24VAC from W to C. The

seven segment LED display will show

H

HT

T 1

1

.

2. The IFC performs a self-check routine and then

confirms that the:

a. Main thermal limits (HI LIMIT), burner box

limit (BBOX LIMIT), and reverse air flow

(RAF) switches are closed by sending 24VAC

out of the HLO terminal and monitoring the

HLI input for 24VAC.

b. The IFC then checks the inducer and blower

motor communications.

3. Once step 2a and 2b are confirmed, the variable

speed inducer motor is energized and performs a

30 seconds pre-purge and then shuts down.

4. Once the pre-purge, the igniter warm up period

begins.

a. Eight seconds after the ignitor warm-up

begins, the inducer is energized and ramps

up to meet the Light-Off pressure.

b. Once the Light-Off pressure feedback is

sensed and the igniter warm-up time has

elapsed (~17 seconds), the 1

st

stage gas

valve is energized.

N

No

otte

e:: If the feedback is not correct, the IFC

will time out and flash the proper fault

code.

5. The burner system will ignite, providing current to

the flame sensor. Proof of flame must be

established within 4 seconds or a retry will occur.

N

No

otte

e:: Typical flame current ranges from 0.75 –

3.0µa.

6. Once flame sense has been established, the igniter

is de-energized, the blower on timer begins and the

inducer ramps to the “Pre-Run” speed. During this

transition, the combustion pressure increases until

the Pre-Run pressure is sensed.

7. Once the Pre-Run pressure feedback is sensed, the

IFC will energize the 2nd stage of the gas valve.

8. After the blower on timer has completed, the indoor

blower will run at the selected gas heating speed.

9. The seven segment LED will alternately read:

•

H

HT

T 1

1

= Gas heating, Stage 1

•

A

AR

RF

F

= Airflow

•

0

06

60

0

= 600 calculated cfm (value shown x 10)

(example value)

10. When the temperature raises enough to satisfy the

thermostat setting, contacts R-W will open.

11. The gas valve relay will open, closing the gas valve.

The inducer continues to run for ~5 seconds to

remove any combustion by-products from inside

the furnace.

12. The indoor blower continues to run to remove heat

from the heat exchangers. The Heat Off Delay is

field adjustable. The seven segment LED will return

to

1

1 D

DL

L

(Idle) assuming there is no other demand

from the thermostat, i.e., continuous fan call.

S

Siin

ng

glle

e S

Stta

ag

ge

e C

Co

oo

olliin

ng

g

N

No

otte

e:: Factory supplied Y1-O jumper must remain in

place for proper seven segment LED readout. If

removed, seven segment LED will read

H

HP

P 1

1

1. R-Y1-G contacts on the thermostat close sending

24VAC to the Y1 and G low voltage terminals on the

IFC. Technician should read 24VAC between Y1-B/C

and between G-B/C.

2. 24VAC is sent to the OD unit via thermostat wiring.

3. The indoor blower ramps to the cooling airflow.

The seven segment LED for example will alternately

read:

•

C

CL

L 1

1

= Cooling, Stage 1

•

A

AR

RF

F

= Airflow

•

0

08

80

0

= 800 calculated cfm (value shown x 10)

4. When the temperature is lowered enough to satisfy

the thermostat setting, contacts R-Y-G will open.

5. The OD unit shuts off and the indoor blower shuts

off, unless a blower off delay has been enabled in

the IFC setup menu options. The seven segment

LED will read

1

1 D

DL

L

= Idle, no thermostat demand.