Installation Instructions

Page 27

Pub. No. 41-5016-12

▲

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the detec-

tion of leaks to check all connections. A fire or explosion may

result causing property damage, personal injury, or loss of life.

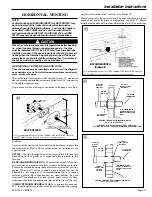

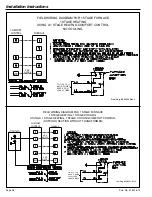

GAS PIPING

The upflow/horizontal furnace is shipped standard for left side

installation of gas piping. A knockout is provided on the right side

for an alternate gas piping arrangement. See Figure 32.

The installation of piping shall be in accordance with piping codes

and the regulations of the local gas company. Pipe joint compound

must be resistant to the chemical reaction with liquefied petro-

leum gases.

Refer to piping Table 8, for delivery sizes. Connect gas supply to

the unit, using a ground joint union and a manual shut-off valve

as shown in Figures 32 & 33. National codes require a condensa-

tion drip leg to be installed ahead of the controls as shown in

Figures 32 & 33.

The furnace and its individual shut-off valve must be discon-

nected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig

(3.5 kPa).

The furnace must be isolated from the gas supply piping by closing

its individual manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5 kPa).

▲

CAUTION

!

Use a backup wrench on the gas valve when installing gas

piping to prevent damage to the gas valve and manifold

assembly.

NOTE:

Maximum pressure to the gas valve for natural gas is

13.8" W.C. Minimum pressure is 5.0" W.C. Maximum

pressure to the gas valve for propane is 13.8" W.C.

Minimum pressure is 11.0" W.C.

All gas fittings must be checked for leaks using a soapy

solution before lighting the furnace. DO NOT CHECK WITH

AN OPEN FLAME!

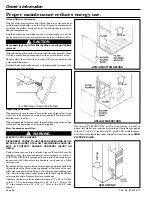

COMBUSTION AND INPUT CHECK

1. Make sure all gas appliances are off except the furnace.

2. Clock the gas meter with the furnace operating (determine

the dial rating of the meter) for one revolution.

3. Match the “Sec” column in the gas flow (in cfh) Table 10 with

the time clocked.

4. Read the “Flow” column opposite the number of seconds

clocked.

5. Use the following factors if necessary:

For 1 Cu. Ft. Dial Gas Flow CFH = Chart Flow Reading ÷ 2

For 1/2 Cu Ft. Dial Gas Flow CFH = Chart Flow Reading ÷ 4

For 5 Cu. Ft. Dial Gas Flow CFH = 10X Chart Flow Reading ÷ 4

6. Multiply the final figure by the heating value of the gas

obtained from the utility company and compare to the nameplate

rating. This must not exceed the nameplate rating.

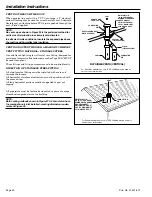

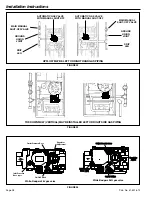

Gas Valve Adjustment

Changes can be made by adjusting the manifold pressure (See

Table 11), or changing orifices (orifice change may not always be

required). To adjust the manifold pressure:

1. Turn off all electrical power to the system.

2. Attach a manifold pressure gauge with flexible tubing to the

outlet pressure boss marked “OUT P” on White-Rodgers gas

valve model 36G or 36J. See Figure 34 for White-Rodgers

gas valve model 36J and model 36G.

3. Loosen (Do Not remove) the pressure tap test set screw one

turn with 3/32" hex wrench.

a. The pressure tap adjustment kit (KIT07611) contains

a 3/32" hex wrence, a 5/16" hose and a connector and can

be ordered through Global Parts.

4. Turn on system power and energize valve.

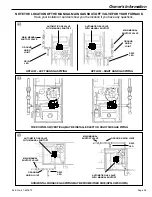

5. Adjust gas heat by removing the adjustment regulator cover

screw.

a. To increase outlet pressure, turn the regulator adjust

screw clockwise.

b. To decrease outlet pressure, turn the regulator adjust

screw counterclockwise.

c. Adjust regulator until pressure shown on manometer

matches the pressure specified in Table 11.

1. The input of no more than nameplate rating and no less

than 93% of the nameplate rating, unless the unit is

derated for high altitude.

d. Replace and tighten the regulator cover screw securely.

6. Cycle the valve several times to verify regulator setting.

a. Repeat steps 5-6 if needed.

7. Turn off all electrical power to the system.

8. Remove the manometer and flexible tubing and tighten the

pressure tap screw.

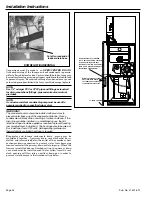

TABLE 9

ORIFICE SIZES

INPUT

RATING

BTUH

NUMBER

OF

BURNERS

MAIN BURNER ORIFICE

DRILL SIZE

NAT. GAS

LP GAS

40,000

60,000

80,000

100,000

120,000

2

3

4

5

6

45

45

45

45

45

56

56

56

56

56

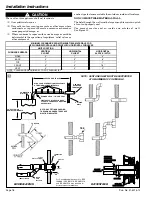

TABLE 8

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

LENGTH OF PIPE

10

20

30

40

50

60

70

1/2

132

92

73

63

56

50

46

3/4

278

190

152

130

115

105

96

1

520

350

285

245

215

195

180

1-1/4

1050

730

590

520

440

400

370

This table is based on pressure drop of 0.3 inch W.C. and 0.6 SP.GR. gas