Installation Instructions

Page 13

Pub. No. 41-5016-12

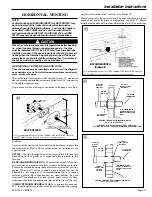

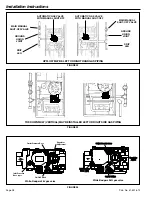

NOTE:

It is recommended that the first joints from the furnace be

connected and sealed with high temperature RTV. This will

enable the pipes to be removed later without cutting.

Be sure to properly support these joints.

BONDING OF PVC

Commercially available solvent cement must be used to join the

pipe and fittings. Follow instructions on the container carefully.

Procedure for Cementing Joints:

1. Cut pipe square, remove ragged edges and burrs. Chamfer end

of pipe, then clean fitting socket and pipe joint area of all dirt,

grease, moisture or chips.

2. After checking pipe and socket for proper fit, wipe socket and

pipe with cleaner-primer. Apply a liberal coat of primer to inside

surface of socket and outside of pipe.

DO NOT ALLOW PRIMER TO DRY BEFORE APPLYING

CEMENT.

3. Apply a thin coat of cement evenly in the socket. Quickly apply

a heavy coat of cement to the pipe end and insert pipe into fitting

with a slight twisting movement until it bottoms out.

4. Hold the pipe in the fitting for 30 seconds to prevent tapered

socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit, tem-

perature and humidity.

NOTE:

Follow venting instructions carefully when using PVC cement.

IMPORTANT:

All joints must be water tight. Flue condensate is somewhat acidic,

and leaks can cause equipment damage.

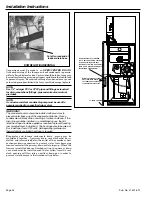

Connection of the pipe and collar of the

combustion air inlet

should just be a friction fit. It is recommended that the inlet air

joint be sealed with RTV type sealant to allow the joint to be

separated for possible future service. The inlet and vent pipes

must be properly supported throughout the entire length.

Connection of the

vent pipe

to the vent collar should also be

accomplished using RTV type sealant. This type sealant provides

a connection which remains flexible and can be separated in the

future if service needs require the removal of the vent pipe for

service or clearance.

NOTE:

To ensure proper operation at the vent lengths indicated, the

combustion air inlet and vent terminals should be in the same

pressure zone. Terminating the vent and inlet in different

pressure zones will change the maximum vent lengths and

may cause nuisance tripping of the pressure switch(es). The

amount of change can not be predicted. The selection of the

inlet and outlet terminal locations are the responsibility of the

designer/installer. If the installer chooses separate pressure

zones for the terminals, the combustion air inlet termination

must be in the higher (more positive) pressure zone.

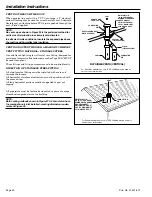

Seal

VENT PIPE

with RTV sealant

Seal

INLET AIR PIPE

with RTV sealant

Front of Furnace

VENT AND INLET AIR CONNECTIONS

f

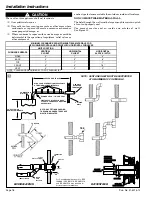

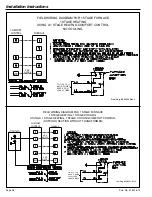

TABLE 7

PLASTIC PIPE DESIGNATIONS

PVC

ASTM STANDARD

PIPE TYPE

ALLOWABLE TEMPERATURE

MARKING

F891

CELLULAR CORE

*158

ASTM F891

D2665

DWV PIPE

**158

ASTM D2665

D1785

SCH 40, 80, 120

**158

ASTM D1785

D2241

SDR SERIES

**158

ASTM D2241

CPVC

ASTM STANDARD

PIPE TYPE

ALLOWABLE TEMPERATURE

MARKING

D2846

CPVC 41

**212

ASTM D2846

F441

SCH 40, 80

**212

ASTM F441

F442

SDR SERIES

**212

ASTM F442

ABS

ASTM STANDARD

PIPE TYPE

ALLOWABLE TEMPERATURE

MARKING

D2661

SCH 40 DWV

***180

ASTM D2661

F628

SCH 40 DWV CELLULAR CORE

***180

ASTM F628

* - Allowable temperatures based on classifications covered in ASTM D4396 [Deflection Temps Under Load (264 PSI)]

** - Allowable temperatures based on classifications covered in ASTM D1784 [Deflection Temps Under Load (264 PSI)]

*** - Allowable temperatures based on classifications covered in ASTM D3965 [Deflection Temps Under Load (264 PSI)]