30 - FORM NO. 56041704

American-Lincoln

6150

SWEEPING SYSTEM SERVICE

MAIN BROOM

To prevent the broom from “setting” in one direction and to provide the maximum life of the broom it is

recommended that the broom be turned end for end periodically.

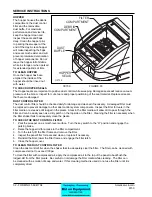

TO CHECK THE MAIN BROOM SWEEP PATTERN

Check the main broom sweep pattern after changing the broom or when poor sweeping performance is

encountered while sweeping.

1. While the machine is not moving, lower the main broom to the “SWEEP” position and let machine sweep

in one spot for a short period of time.

2. Before moving machine, raise main broom lever to the “UP” position and move the sweeper forward

enough to see the pattern left by the main broom bristles on the fl oor.

3. Check the width of the pattern on the fl oor to determine if the main broom requires adjustment.

-A normal sweep pattern left on the fl oor will be between 1 and 2 inches wide.

-A pattern that is more than 2 inches wide indicates the broom linkage needs to be adjusted “UP”

-A pattern that is less than 1 inch wide indicates the broom linkage needs to be adjusted “DOWN”

TO ADJUST THE MAIN BROOM HEIGHT

When changing the sweep height adjustment it is recommended that the bolt be adjusted 1 turn at a time,

After adjustment, re-check the sweep pattern to determine if further adjustment is necessary.

-Turn the adjustment knob counter-clockwise to INCREASE the sweep pattern width.

-Turn the adjustment knob clockwise to DECREASE the sweep pattern width.

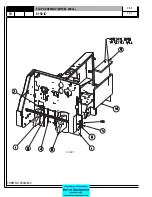

TO REPLACE THE MAIN BROOM

The Main Broom should be replaced when the bristles become worn to less than 2”. The main broom is held

in place by the right side broom door. This feature provides for easy removal and installation of the main

broom without the need for special tools or equipment. Follow the instructions below for main broom removal

& replacement.

1. Park sweeper on a smooth level surface, engage parking brake, turn key switch “OFF”, place the main

broom lever in the “SWEEP” position.

2. Lift the door latch to open the right side broom door.

3. Swing the broom drive idler hub out to clear the main broom.

4. Remove the broom from the broom compartment.

5. Install the replacement broom. Pay special attention to the slots on the broom, it may be necessary to

rotate the broom so the tabs on the drive hub align with the slots on the broom.

6. Swing the idler hub to engage the main broom and close the access door. Check the door latch for proper

engagement when closed.

7. Check the Main Broom sweep pattern and adjust as necessary.

MAIN BROOM LEVEL ADJUSTMENT

The main broom level is factory set and should not need adjustment. If the level becomes out of adjustment

and the broom bristle contact pattern is not an even 2” to 3” wide, the broom arm lift frame will need to be

adjusted. The frame is supported by two plates located inside the broom doors. The carriage bolts (part

number 2-00-05187) that secure the plates to the frame will need to be loosened. The frame can then be

leveled and the bolts retightened.

SERVICE INSTRUCTIONS

Summary of Contents for 6150

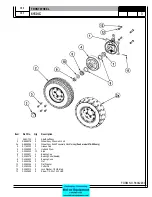

Page 39: ...FORM NO 56042480 6150 IC 4 06 5 REAR WHEEL 07 10 ...

Page 41: ...FORM NO 56042480 6150 IC 6 06 5 VAC FAN 07 10 ...

Page 45: ...FORM NO 56042480 6150 IC 10 06 5 FLAP ASSEMBLY WHEEL WELL 07 3 C 1227 ...

Page 51: ...FORM NO 56042480 6150 IC 16 06 5 C1250 H46 H43 H39 H47 H53 SIDE BROOM ASSEMBLY 07 3 ...

Page 53: ...FORM NO 56042480 6150 IC 18 06 5 SIDE BROOM LIFT SYSTEM 07 10 ...

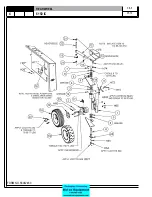

Page 57: ...FORM NO 56042480 6150 IC 22 06 5 BROOM CHAMBER FLAPS SEALS 07 10 ...

Page 59: ...FORM NO 56042480 6150 IC 24 06 5 BRAKE PEDAL 80805 1 6 05 07 3 ...

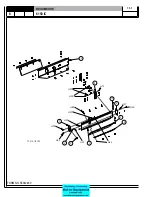

Page 63: ...FORM NO 56042480 6150 IC 28 06 5 SEAT FLOOR ASSEMBLY 07 10 ...

Page 71: ...FORM NO 56042480 6150 IC 36 06 5 CONTROL RELIEF VALVE 3 CYL KUBOTA GAS DIESEL 07 3 ...

Page 73: ...FORM NO 56042480 6150 IC 38 06 5 FWD REV CONTROL 2 CYL KAWASAKI GAS 07 10 ...

Page 75: ...FORM NO 56042480 6150 IC 40 06 5 FW REV CONTROL 3 CYL KUBOTA GAS DIESEL 07 3 ...

Page 81: ...FORM NO 56042480 6150 IC 46 06 5 FUEL TANK GAS 07 10 ...

Page 83: ...FORM NO 56042480 6150 IC 48 06 5 FUEL TANK DIESEL 07 10 ...

Page 87: ...FORM NO 56042480 6150 IC 52 06 5 80806 2 2 05 HOPPER COVERS GASKET ASSEMBLY ...

Page 91: ...FORM NO 56042480 6150 IC 56 06 5 H26 H80 H86 H26 H98 H22 C 1207 9701 DUMP DOOR ...

Page 97: ...FORM NO 56042480 6150 IC 62 06 5 HYDRAULIC PUMP 3 CYL KUBOTA GAS DIESEL 07 3 80851 SHT01 ...

Page 99: ...FORM NO 56042480 6150 IC 64 06 5 ENGINE COVER 30 25 32 31 80813 0 3 07 ...

Page 101: ...FORM NO 56042480 6150 IC 66 06 5 80841 8 05 ACCESS COVER ASSEMBLY ...

Page 105: ...FORM NO 56042480 6150 IC 70 06 5 ENGINE 3 CYL KUBOTA GAS 07 10 ...

Page 107: ...FORM NO 56042480 6150 IC 72 06 5 ENGINE 3 CYL KUBOTA DIESEL 07 10 ...

Page 109: ...FORM NO 56042480 6150 IC 74 06 5 ENGINE 3 CYL DUAL FUEL LP 07 10 ...

Page 113: ...FORM NO 56042480 6150 IC 78 06 5 80839revF 8 05 HYDRAULIC HOSE DIAGRAM 2 CYL ...

Page 125: ...FORM NO 56042480 6150 IC 90 06 5 DECALS 08 7 ...

Page 127: ...FORM NO 56042480 6150 IC 92 06 5 DECALS continued 07 10 ...

Page 129: ...FORM NO 56042480 6150 IC 94 06 5 C1335 7 04 2 CYLINDER LP CE MODELS ONLY ...

Page 136: ...101 FORM NO 56042480 6150 IC 06 5 HYDRAULIC SCHEMATIC 2 CYL GAS LP DIESEL 08 7 ...

Page 138: ...103 FORM NO 56042480 6150 IC 06 5 HYDRAULIC SCHEMATIC 3 CYL KUBOTA GAS DIESEL ...