17

17

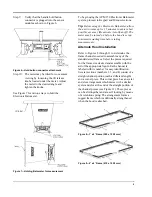

The duct in Figure 17 has a horizontal dimension

between 30 and 36 inches, requiring six points (or

six traverse lines). The duct’s vertical dimension is

less than 30 inches, requiring five points (or five

traverse lines).

Notice of Disclaimer

TSI Incorporated has made a good faith effort to

provide reliable information regarding the use of

the APM 150 to conduct a duct traverse. However,

we cannot guarantee that the material

presented

here will guarantee conformance to any particular

method or specification, or that this material is free

from error. Traverse methods outside of the USA

will be slightly different. TSI recommends

purchasing a copy of the duct traverse

specification you require from an approved

regulatory or professional organization.

For further information, refer to the 1993

ASHRAE

Fundamentals Handbook

Section 13, or to

ASHRAE Standard 111 (1988).

APPENDIX B:

TIME CONSTANT AVERAGING TECHNIQUE

The averaging technique is common to many types

of instrumentation. It also tends to increase the

display rate of the microprocessor on the LCD. In

other words, the lower the time constant value, the

higher the percentage of the new value is

displayed at an increased time rate.

This technique uses a percentage of the newly

acquired value and adds it to a percentage of the

“old” value. The two percentages must add up to

100%. The meter then displays the resultant value.

This displayed value then becomes the “old” value

while a new pressure is being measured. Then the

process starts over. By

using less than 100% of the

new value for the displayed reading, a more stable

displayed reading results. The following table

shows the [

] value and the percentages of new

and old values that will be used.

In any circumstance, if the new value is more than

50% different than the old value, 100% of the new

value will be used. This “override” percentage

allows the meter to quickly attain a new value

when the higher [

] settings are used, and

provides the desired damping to typical input

fluctuations. Without this feature, the meter would

take a long time to reach its final value when

exposed to large changes in input value.

Setting

New Value

%

Old Value

%

Time to Reach 95% of input

is less than override %

Time to reach input if

more than override %

Override

%

1

100%

0%

1.5 seconds

1.5 seconds

50%

2

50%

50%

6.0 seconds

1.5 seconds

50%

3

25%

75%

12 seconds

1.5 seconds

50%

4

10%

90%

34 seconds

1.5 seconds

50%

5

5%

95%

68 seconds

1.5 seconds

50%

Note:

The time at 1.5 seconds is the time to reach input if more than override % column corresponds to two update intervals.

Depending on when in the update cycle the stop change would occur, this is the maximum time which would be needed to see the

change. It is possible to view the change after one update.

Summary of Contents for APM 150

Page 1: ...Electronic Balometer with APM 150 Meter OWNER S MANUAL...

Page 4: ......

Page 26: ...22 22...

Page 76: ......