9

Series AE1L, AE.E, AE.N, AE.H, AE.V, AED1E, AED2N

Design ID, ZD

the joint oil, refer to the disassembly and assembly in-

structions.

7.1.2.2 Bearing of the drive shaft and lubrication of the

bearings

Bearing of the drive shaft in the bearing bracket

through re-greasable angular contact and groove ball

bearings.

Note:

The groove ball bearing is greased for life with

vertical pump installation.

Roller bearing lubricants

We recommend the following roller bearing lubricants

or others of a proven similar quality for lubricating the

ball bearings. The sequence of manufacturers is no

quality rating.

Manu-

facturer

Brand

Name in acc.

with DIN 51825

Agip

Agip GR MU3

K3K-20

ARAL

Aralub HL3

K3K-20

BP

BP Energrease LS3

K3K-20

ESSO

BEACON 3

K3N-30

Fuchs

RENOLIT FWA 220

K3N-20

Klüber

MICROLUBE GL 263

K3N-20

Mobil-Oil

Mobilux 3

K3K-20

Shell

Shell Alvania Grease R3

K3N-30

SKF

SKF Grease LGMT3

K3K-30

If none of the above roller bearing lubricants are

available, we recommend using a multi-purpose lubri-

cant on lithium basis in any case, which corresponds

to one of the above DIN names.

The mixing of greases with different basic oils and

thickeners leads to reduced lubricating properties and

should therefore be avoided.

The table in Chapter 7.1.2.6 shows the allocation of

the pump sizes to the amount in grease per gram.

Relubrication period

The bearings must be relubricated each 4,000 operat-

ing hours.

Relubrication

Relubrication takes place via the lubricating nipple

(119) screwed into the bearing bracket (110). Con-

tinue regreasing until the old grease emerges from

the bearing cover (131). Scrape the old grease off.

7.1.2.3 Shaft sealing

Shaft sealing either takes place via a stuffing box or a

mechanical seal.

•

Stuffing box

Possibly increased leaks on the stuffing box during

the first operating hours normally decrease on their

own during the warm-up time.

If necessary, slightly tighten the hexagon nuts (202)

on the gland (203).

Please observe that there has to be a slight leak on

the stuffing box. This dissipates the friction heat that

forms on the sealing surface.

If the leaking losses increase disproportionately and if

this cannot be reduced by slightly tightening the

hexagon nuts (202) several times, the packing rings

have lost their shape elasticity and must be replaced.

!

Dismounting the old packing rings and clean-

ing the stuffing box casing

After relieving the pump from pressure and re-

moving the gland, you can take out the old pack-

ing rings. Use a packing puller with elastic shaft.

Afterwards, carefully clean the stuffing boxspace

and the drive shaft in the area of the packing

rings. Used-up drive shafts respectively shaft pro-

tection casings must be renewed (see disassem-

bly and assembly instructions).

!

Installing the packing rings

As a rule, you may only install

packing rings that correspond to

the required operating conditions of the pump.

The dimensions and required number of pre-

pressed packing rings and ring cuts respectively

cut lengths are listed in the table in Chapter

7.1.2.6.

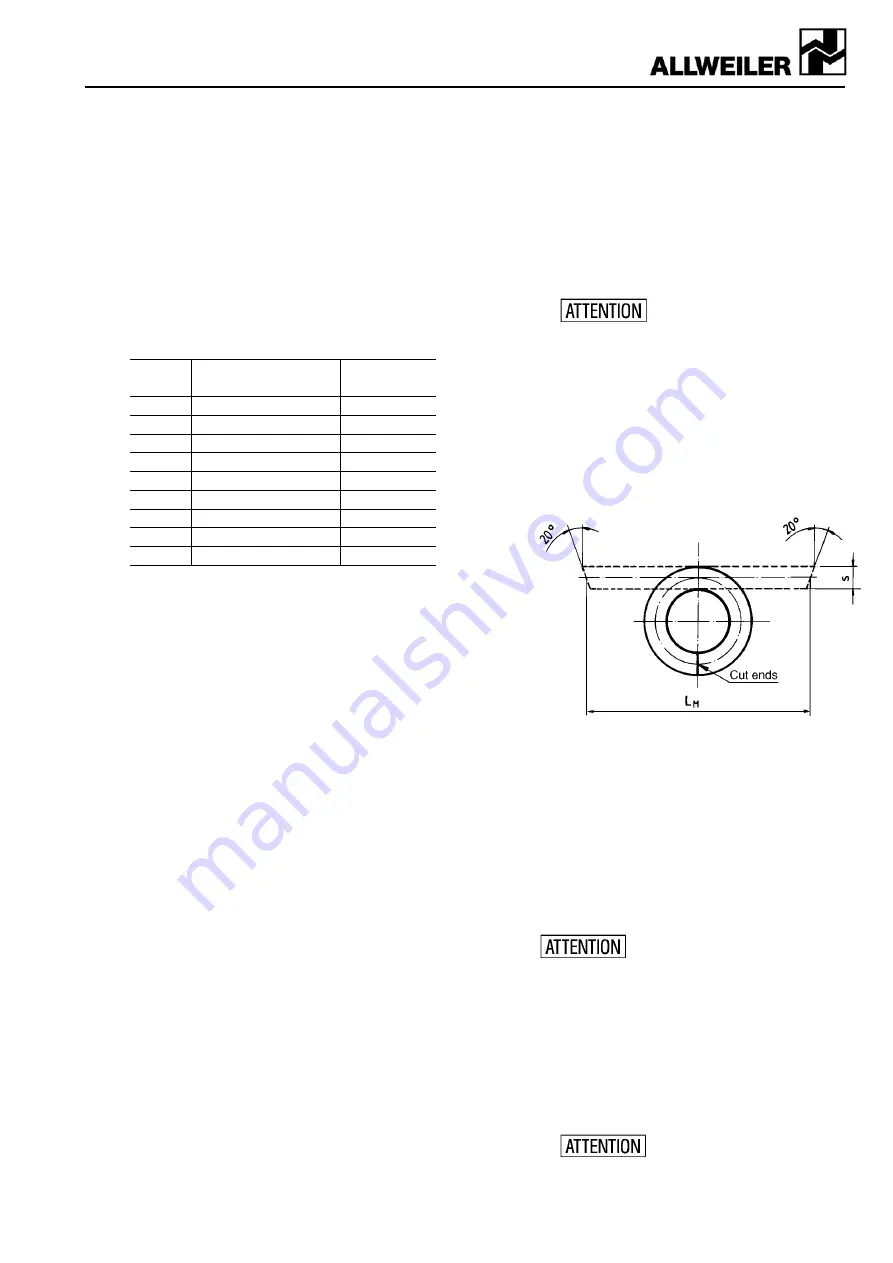

With cuts

we recommend the straight vertical cut

to the shaft. In order to achieve a gap-free, paral-

lel position of the cutting ends when closing the

packing ring, the cutting angle should be approx.

20° to both cut ends (see figure 1).

Figure 1: Cutting packing rings

Pre-pressed packing rings or ring cuts

have to be

carefully turned open axial and radial so that they can

just about be slid across the shaft. Bending the rings

may lead to damages.

When installing in the packing space, carefully rebend

the packing rings to ring shape. The cutting joints

have to be shifted by 90° here. Each ring has to be

slid into the Stuffing boxspace individually with the

cutting ends facing forward by means of the gland.

The sealing chamber ring or flushing ring have to be

installed sequentially.

You may never use pointed objects

for this work. Danger of damaging

the shaft and deforming the packing material!

!

Start-up the stuffing box after re-packaging

The stuffing box may only be tightened slightly

prior to start-up. When starting the pump, 50 to

200 drops per minute are an admissible leakage

quantity.

During the warm-up process of approx. 30 min-

utes, adjust a minimum leakage of 2 to 20 drops

per minute by evenly tightening the gland (203)

step by step via the hexagon nuts (202).

The stuffing box temperature

may not rise abnormally during

this process. Approx. 20° to 60°C above the con-

veyor liquid temperature are admissible. In case