19

Series AE1L, AE.E, AE.N, AE.H, AE.V, AED1E, AED2N

Design ID, ZD

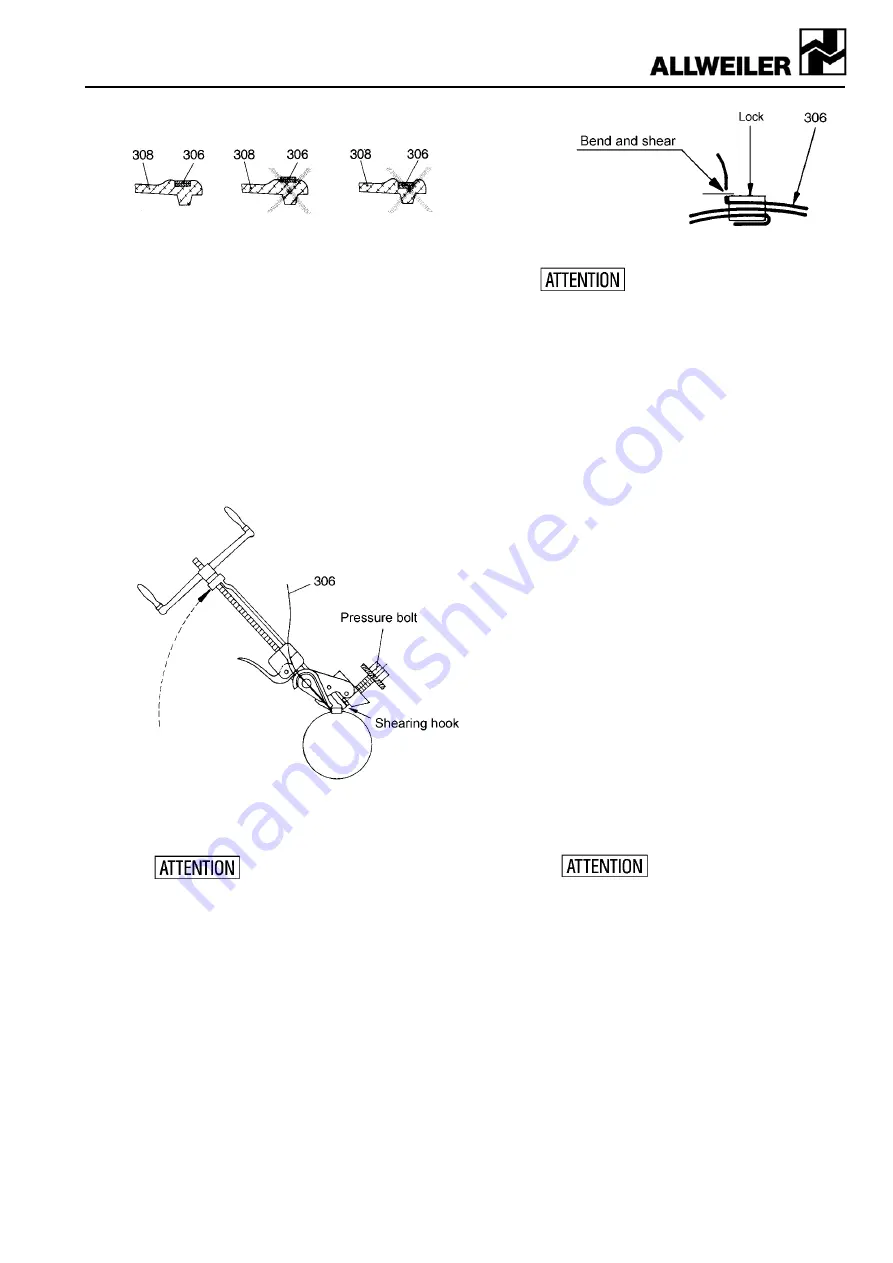

Right Wrong Wrong

Joint clamp (306)

has slightly

drawn in the

outer collar form

and has a tight

fit.

Joint clamp (306)

is too loose and

may slide off.

Joint clamp (306)

too tight. Collar is

damaged

(stripped off).

Figure 14: Tightening the joint clamps

!

Check that the joint clamp (306) is positioned in

the joint collar (308) across the entire circumfer-

ence in the collar groove.

!

Slowly turn the clamping tool by approx. 60° up-

wards until the shear hook reaches behind the

joint clamp lock (see figure 15).

!

Tighten the pressure screws by hand until the joint

clamp has a tight fit.

Figure 15: Shearing the joint clamp

!

Turn the pressure screw with a spanner or ratchet

clockwise until the joint clamp is sheared off.

If the joint clamp is lifted up

slightly on the sheared off side,

adjust this by careful realignment. Do not hammer

or hit on the joint clamp lock, otherwise you may

damage the collar.

Note:

Joint clamps made of hastelloy cannot be

sheared off with the clamping tool. After canting at

the joint clamp lock, shear off the joint clamp with

a pair of metal shears and deburr the cutting

edges (see figure 16).

•

Clamping with the clamping tool PoK-It II

!

When using the clamping tool PoK-It II, cant the

joint clamp (306) after tightening on the joint

clamp lock by swiveling the clamping tool in such

a way that the clamp cannot slide back through

the lock. After canting at the joint clamp lock,

shear off the joint clamp with a pair of metal

shears and deburr the cutting edges (see figure

16).

Figure 16: Canting and shearing the joint clamp

Check whether the joint clamp is bent

in such a way that it cannot slide

back through the joint clamp lock (see figure 16). If

this is not the case, remove the joint clamp and re-

place it with a new one.

7.2.2.5 Installing the joint shaft and the drive-side joint

!

Attach the drive-side joint to the drive shaft (118)

as described in Chapter 7.2.2.4.

!

Slide the joint shaft into the joint cup of the drive

shaft (118).

!

Secure the joint collar (304) as illustrated with a

puncher blow.

!

Pull on the joint collar (308), fill the joint cavity with

joint oil and attach the joint clamps as described.

!

Insert the g

asket for suction casing

(501).

!

Slide the suction casing (505) across the rotor

(401). Make sure that the finely crafted rotor is not

damaged here.

!

Attach the suction casing (505) with the hexagon

screws (606), the serrated lock washers (608) and

the hexagon nuts (607) on the bearing bracket

(110).

Note:

Prior to tightening hexagon nuts (607), align

the connection flange of the suction casing (505).

Observe the proper position of the connections in

the stuffing box (204) respectively mechanical

seal housings (214). See our fitting dimension

sheets.

7.2.2.6 Installing the stator

!

Slide the O-ring (513) and reducer flange (512), if

provided, into the suction casing (505).

!

Prior to pulling on, grease the stator (402) and ro-

tor (401) with lubricant (silicone oil, polydiol, soft

soap or similar).

Do not use any normal oil.

!

With stators made of plastic or metal, insert stator

seals (403) and (404).

Note:

With stators made of plastic, the stator seal

(403) with the O-ring must always lie on the outlet

side.

!

With multi-part stators (402) pull on the stator

(402) with the center hole or center groove point-

ing towards the support (612) onto the rotor (401).

Note:

In case of difficulty, turn the stator (402)

with pliers at the same time. To do so, arrest the

drive shaft (118).

!

With multi-part stators, turn the stators (402) in

such a way that the fixing pieces (631) reach into

the groove respectively boring of the stators (402).

!

Slide the support (612) (if provided) onto the

clamp bolts (611).

!

Screw the pressure casing (504), support (612), if

provided, stator (402) and suction casing (505)

together with the clamp bolts (611) and the hexa-