3

Series AE1L, AE.E, AE.N, AE.H, AE.V, AED1E, AED2N

Design ID, ZD

1.

General

1.1

Application and range of utilization

The eccentric screw pumps are self-priming, rotary

positive-displacement pumps for handling and dosing

low to high-viscosity, neutral or aggressive, pure or

abrasive, gaseous liquids or liquids which tend to

froth, even with fibre and solids contents.

The range of utilization is to be

taken from the order data sheet.

1.2 Performance

data

The exact performance data applying to the pump

are to be taken from the order data sheet and are

engraved on the name plate.

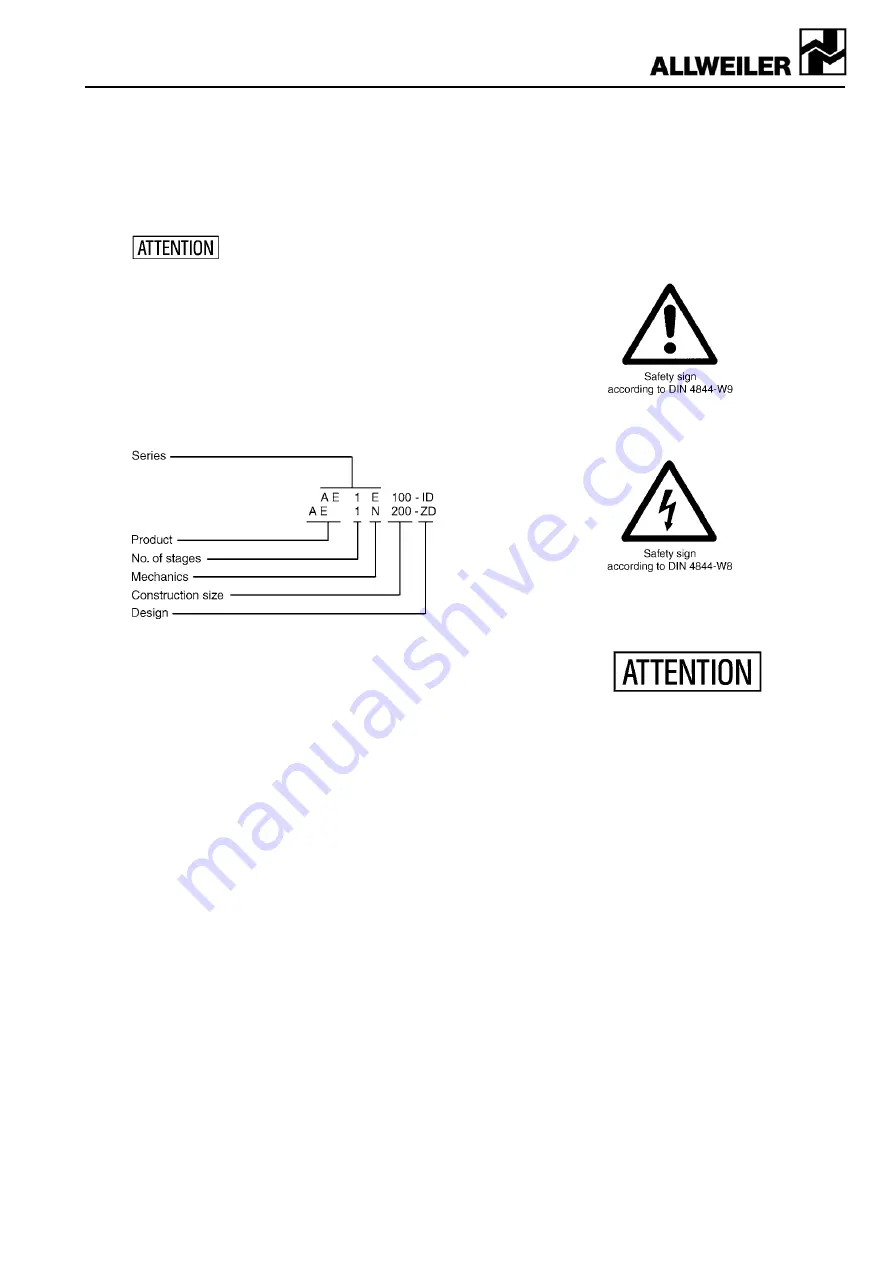

1.3 Abbreviation

The abbreviation of the eccentric screw pumps is set

up according to the following scheme:

Example:

This abbreviation is embossed on the type plate.

1.4 Warranty

Our liability for shortcomings in the supply is laid down

in our delivery conditions. No liability will be under-

taken for any damages caused by non-compliance

with the operating instructions and service conditions.

If at any later date the operating conditions happen to

change (e.g. different liquid pumped, speed, viscosity,

temperature or pressure conditions), it must be

checked by us from case to case and confirmed, if

necessary, whether the pump is suited for these pur-

poses. In case no special agreements were made,

pumps supplied by us may, during the warranty pe-

riod, be opened or varied only by us or our authorized

contractual service stations; otherwise, our liability for

any defects will cease.

1.5 Testing

Prior to leaving our factory, all pumps are subjected to

a leakage and performance test. Only properly oper-

ating pumps leave the factory achieving the perform-

ances assured by us. Thus, compliance with the fol-

lowing operating instructions ensures proper opera-

tion.

2.

Safety

These operating instructions contain basic hints to be

observed in case of installation, operation and main-

tenance. Therefore, prior to mounting and commis-

sioning, these operating instructions must by all

means be read by the fitter as well as the pertinent

expert personnel/customer and must always be avail-

able at the place of installation of the machine/ plant.

Not only are the general safety hints listed under this

main item „Safety“ to be observed, but also the spe-

cial safety hints such as for private use added to the

other main items.

2.1

Marking of hints in the operating instructions

The safety hints contained in these operating instruc-

tions which, in case of non-compliance, may cause

danger to personnel, are particularly marked with the

general danger symbol

in case of warning against electric voltage with

For safety hints, non-compliance with which may

cause dangers to the machine and its functions, the

word

is inserted.

Hints directly attached to the machine such as

!

directional marker

!

signs for fluid connections

must by all means be observed and maintained in

completely legible condition.

2.2

Personnel qualification and personnel training

The personnel for operation, maintenance, inspection

and mounting must have the corresponding qualifica-

tion for these operations. Range of liability, compe-

tence and the supervision of the personnel must be

exactly controlled by the customer. If the personnel do

not have the required knowledge, same must be

trained and instructed. If required, this may be ef-

fected by the manufacturer/ supplier on behalf of the

machine customer. In addition, it must be ensured by

the customer that the contents of the operating in-

structions are fully understood by the personnel.

2.3

Dangers in case of non-compliance with the safe-

ty hints

Non-compliance with the safety hints may result in

danger not only to persons, but also to environment

and machine. Non-compliance with the safety hints

may lead to the loss of any claims for damages. In

detail, non-compliance may,

for example

, entail the

following dangers: