To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected

to ensure that the dryer is properly grounded.

WARNING

W001R1

70

505038

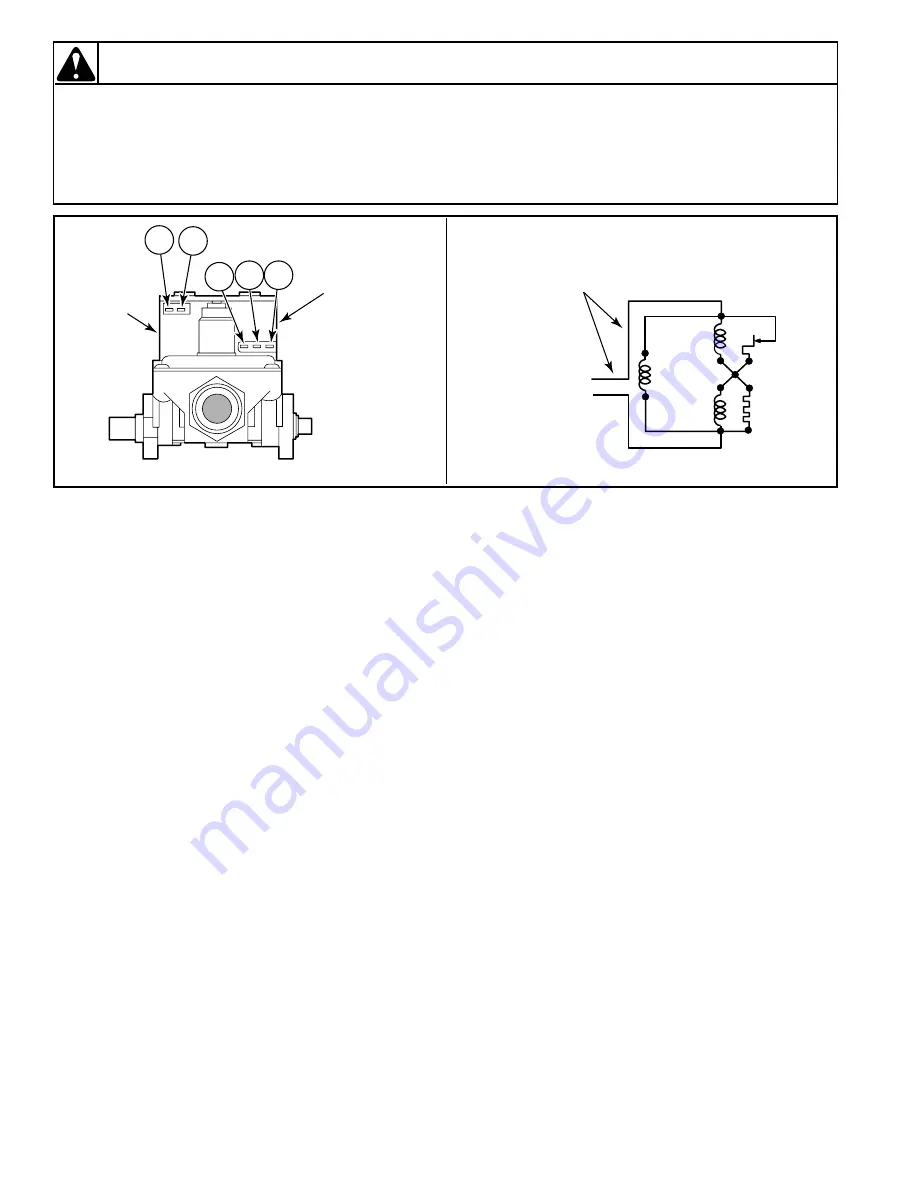

Figure 59

SECONDARY

COIL

HOLDING COIL

AND

BOOSTER COIL

(SPLIT COIL VALVE)

4

1

5

2

3

D267SE3B

SENSOR

SECONDARY

COIL

HOLDING

COIL

BOOSTER

COIL

IGNITER

120 VOLT, 60 HERTZ

ELECTRICAL

SUPPLY LINE

D268SE3A

56. BURNER SYSTEM OPERATION

(Gas Models – Figure 59)

a. Components

This burner has four basic components: a silicon

carbide (glow bar) igniter, burner tube, flame

sensor, and a two-stage gas valve consisting of a

split-coil valve and a secondary coil valve. The

split-coil valve is opened when the dryer

thermostat calls for heat, while the secondary

valve does not open until the igniter has attained

ignition temperature.

b. Pre-Ignition Circuits

When the dryer thermostat calls for heat, circuits

are completed through the holding coil, flame

sensor, booster coil and igniter. Both coils must

be energized to open the split-coil valve. Once

opened, the holding coil can hold the valve open

without assistance from the booster coil. The

flame sensor triggers the current to travel around

the secondary coil and through the igniter,

causing the igniter to get hot.

c. Burner Circuit

In approximately 30 seconds, the igniter attains

ignition temperature and ignition is made. The

heat from the burner flame causes the flame

sensor contacts (located on burner housing beside

the igniter) to open. A circuit is then completed

through the secondary valve coil, opening the

valve and allowing gas to flow.

d. Momentary Power Interruption

Upon resumption of power, flame sensor contacts

will still be open, permitting secondary valve to

open. However, with the secondary coil in the

circuit, the booster coil cannot draw enough

current to open the split-coil valve. When flame

sensor contacts do reclose, the secondary valve

will close, and the burner system will be in the

normal pre-ignition circuit.

e. Flame Failure

In case of flame failure, the flame sensor contacts

will re-close in about 45 seconds. This will close

the secondary valve and the burner system will

be in the normal pre-ignition circuit.

f. Ignition Failure

If flame is not established as flame sensor

contacts open, secondary valve will remain open

until flame sensor contacts re-close. Flame

sensor will continue to recycle the igniter and

secondary valve (about once per minute) until

ignition is made or dryer is turned off.