Maintenance

Algas-SDI Operation and Maintenance Manual – P/N – 54000

16

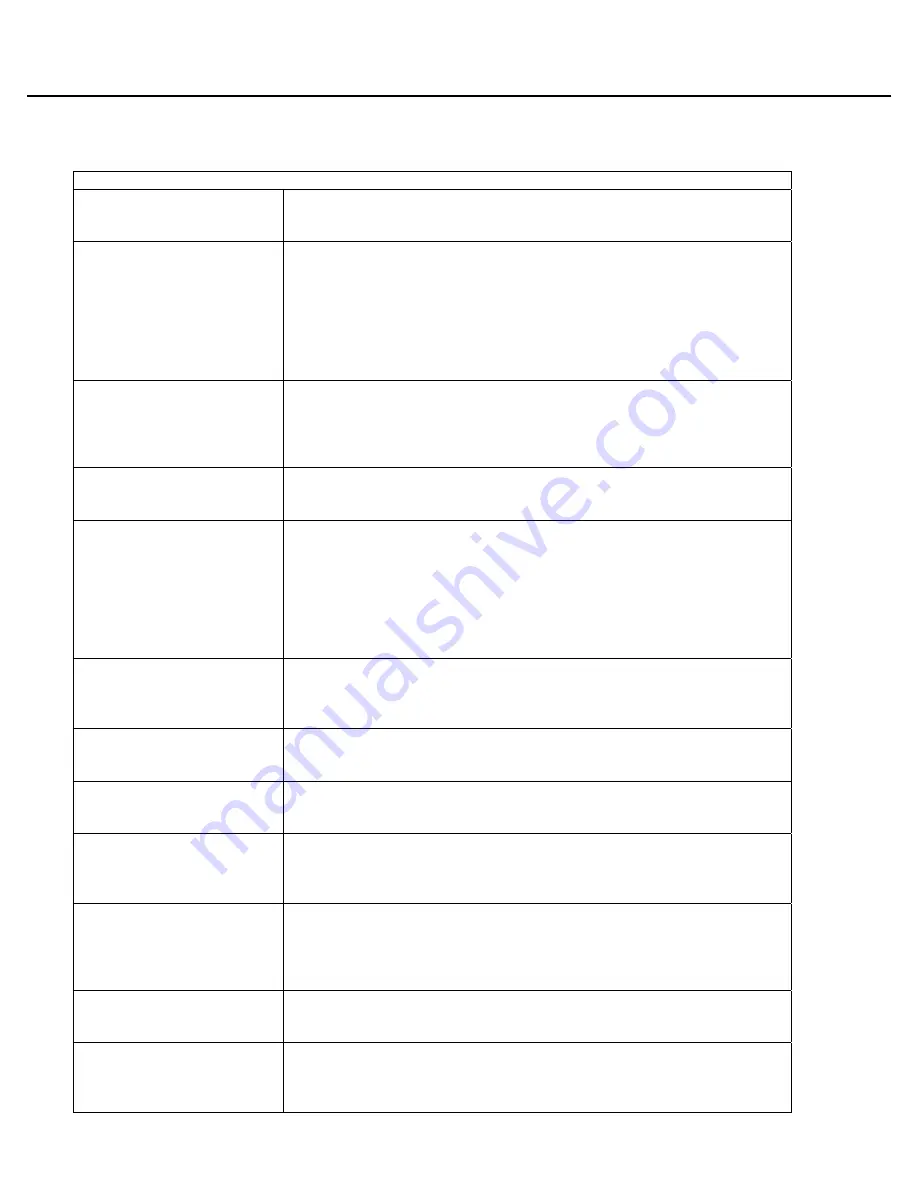

Table 4

– Annual Maintenance Requirements

Annual Maintenance Items

Strainer

Remove the plug and clean the screen. Replace screen if tears or holes

are present. If oils or contaminants are present, it may be necessary to

use a cleaner to remove all of the contaminants.

Thermostat

Check thermostat for proper operation per the

Start-up procedure

.

Establish pilot and turn the thermostat dial counter-clockwise to high,

burners should cycle on. Turn the dial clockwise to the “off” position,

main burner and pilot should both extinguish in a short period of time.

Replace the thermostat if not operating properly (thermostat cannot be

serviced). NOTE: Before replacing the thermostat, be sure the

thermocouple is delivering the proper voltage to the thermostat (see

below).

Thermocouple

Check electrical output of the thermocouple with a millivolt meter. The

thermocouple output (when hot) should be 13 - 30 mV. Lower than 13

mV reading indicates the thermocouple should be replaced. NOTE: Be

careful not to over tighten the thermocouple! First hand tighten and then

turn 1/8

th

turn with wrench.

Pilot Assembly

Inspect pilot flame to ensure flame is enveloping 3/8” to ½” of the

thermocouple tip. Clean pilot orifice. If pilot assembly is corroded or

significantly deteriorated, replace complete pilot assembly.

Main Burner Assembly

Inspect burner tips to ensure each tip has proper flame. For easy access

to clean the burner tips, disconnect burner supply line and remove the

burner from the unit. With compressed air (if possible), blow out main

burner ring prior to cleaning the burner tips. Check orifices and air supply

openings for debris, insects and/or dirt. Clean any plugged or obstructed

orifices. Direct Fired vaporizers built after October 2002 have #66 burner

jet orifices. Vaporizers built after October 2013 have #69 burner jet

orifices.

Flame Spreader Bar

Models 80/40H & 120/60H

Upon initial installation and during periodic maintenance inspections,

check flame spreader bar position to ensure both burners light

simultaneously and smoothly. Straighten spreader bar if it is positioned at

an angle or not positioned on top of the pilot properly.

Liquid Inlet Valve

Use repair kit p/n: 3-0016 to replace internal components of the liquid inlet

valve. See detailed

Liquid Inlet Valve Maintenance Instructions

for further

information.

Capacity Control Valve

Use repair kit p/n: 3-0017 to replace internal components of the capacity

control valve. See detailed

Capacity Control Valve Maintenance

Instructions

for further information.

Vaporizer Tubing

Inspect all tubing for pitting or flaking - run hands along the underside of

each of the tubes to check for signs of corrosion. Replace tubes if

corroded. Disconnect all tubing and blow tubes free of debris. Re-install

tubing to the vaporizer and check and tighten all fittings.

Relief Valves

Inspect all relief valves on the vaporizer, liquid and vapor lines for signs of

corrosion and rain caps. Replace rain cap if it is damaged or missing.

Replace relief valves per manufacturer’s recommended replacement

period. Also replace relief valve if it shows significant corrosion on the

outlet or has relieved.

Burner Regulator

Check regulator delivery pressure at the drip leg and at the burner

pressure port to ensure proper pressure is delivered to the thermostat and

burners. See page 3.

Heat Exchanger

1. Check heat exchanger flue for holes or excessive scale.

2. Remove debris, soot build-up and any obstructions from the

outside surface of the heat exchanger between the fins and in the

area between the heat exchanger and flue. High pressure air or

Summary of Contents for Direct Fired F6-ASME

Page 4: ...This page left intentionally blank...

Page 7: ......

Page 10: ...This page left intentionally blank...

Page 42: ...APPENDIX A TECHNICAL INFORMATION...

Page 43: ...Appendix A This page intentionally left blank...

Page 50: ...Appendix A...

Page 51: ...Appendix A...