13/30

ALFA IN a.s. ©

www.alfain.eu

3. Cut off the curved or damaged end of welding wire and lead it through the

inlet liner

E3,

and the roll into the liner inside the EURO torch connector

(about 5 cm). Make sure, that you use the suitable groove.

4. Put the pressure arm

E2

down in that way, that the teeth or the gear fit and

fix it by setting the lever

E1

into vertical position.

5. Adjust the pressure nut that way that it provides constant movement of

wire but it does not deform wire. By pressing the button

A10

, placed in the

space of the wire feeder, turn on the motor of the feeder. The adjusting

screw is located under the plastic screws

E1

.

6. The spool brake is set by the manufacturer. If necessary, the brake can be

adjusted by a screw

D1

so that while stopping the feed, spool will be

stopped on time (it will avoid excessive release of wire). However, too tight

brake needlessly strains the feeding mechanism and thus slippage may

occur in the wire rolls.

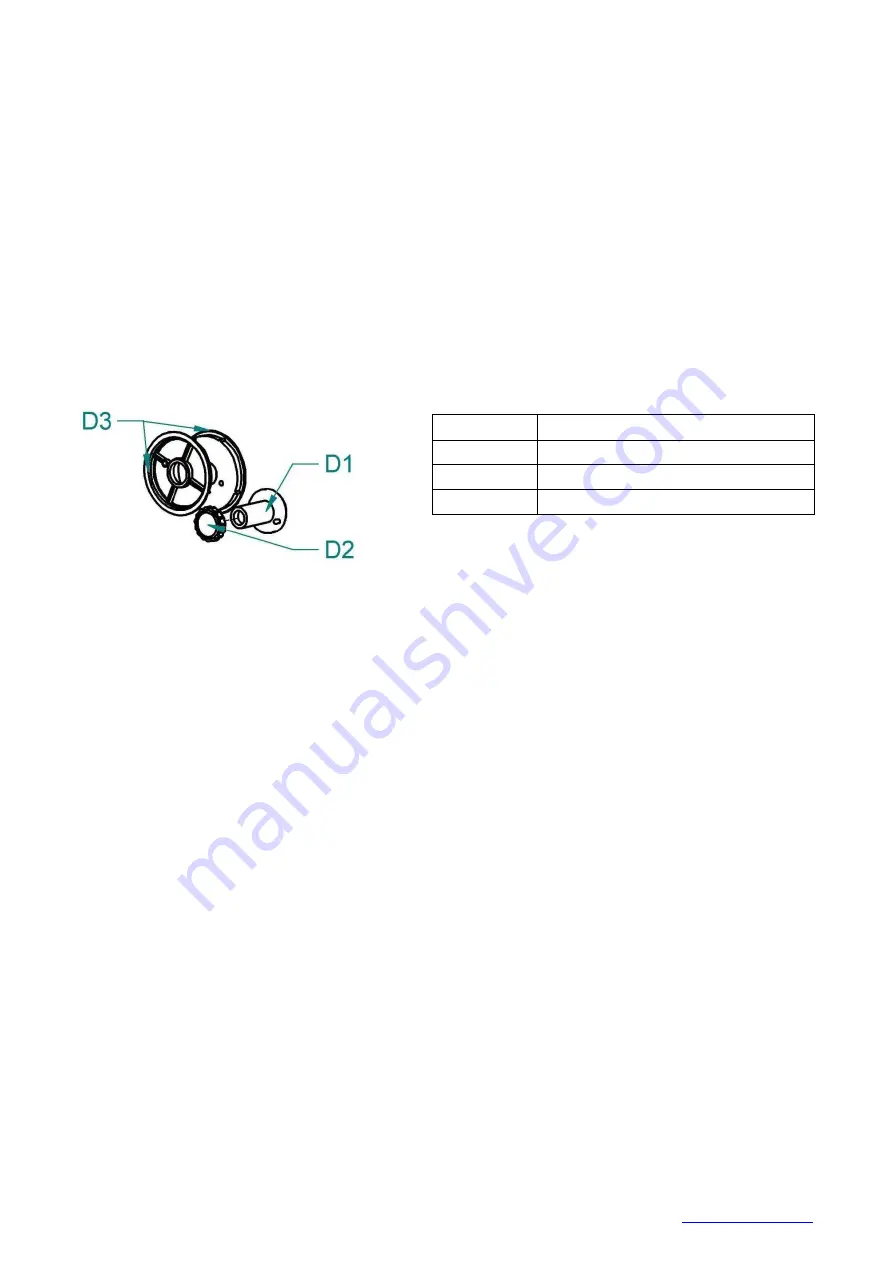

Fig. 5 - Spool holder

ADJUSTING PRESSURE FORCE OF FEED ROLLS

Important thing for reliable operation of the feeding mechanism is the size of

pressure force of feed rolls.

The amount of force depends on the type of welding wire, for aluminum or tube

wire, we choose a smaller pressure force.

If the pressure force is too small, slippage may occur and thus irregular wire

feeding speed.

If the pressure force is too high, it will lead to increased mechanical wear of

bearings and it can damage the machine. Before putting into operation, clean

the rolls from preservative oil.

Pos.

Description

D1

Spool Holder

D2

Nut Spool Holder

D3

Adapter