Page 22 of 68

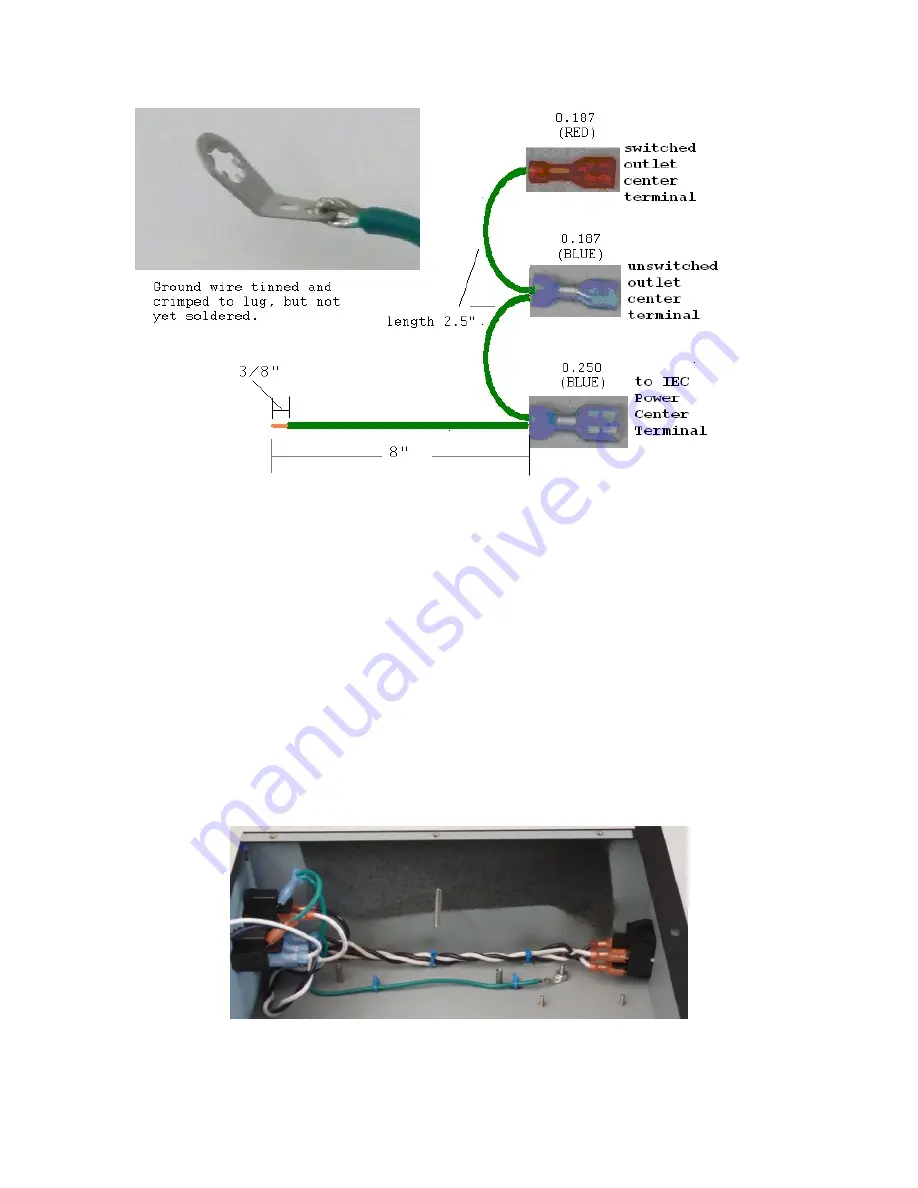

Figure 15-Adding Lug to Ground Harness

Connecting the Chassis Ground

Locate the #6 toothed lug. It’s packed in the “Screw Nut Lug” envelope. Locate the green

ground harness. It has green wire with 3 FASTONs.

1.

Cut the long green wire to 8” length as shown in Figure 15.

2.

Remove 3/8” of insulation from the now 8” wire. Twist and tin the strands. Loop

and crimp the wire on the lug as shown in Figure 15. Solder the wire to the lug.

3.

Connect the blue 0.25” wide FASTON to the center terminal of the IEC power

connector.

4.

Connect the blue 0.187” wide FASTON to the center terminal of the unswitched

outlet.

5.

Connect the red 0.187” wide FASTON to the center terminal of the switched

outlet.

6.

Dress the long green wire toward the ground stud behind the switch as shown in

Figure 16. Use two more cable ties in the tie down positions shown to secure the

ground wire.

Figure 16-AC Power and Ground Wiring

7.

Use a plain 6-32 nut to hold the ground lug on the chassis stud.