6

Subject to change without notice | 83018300lUK – Translation of the original operating manual | ait-deutschland GmbH

10

Transport, Installation,

Assembly

Observe the following when performing all work:

IMPORTANT

The tank must be installed in a frostproof

room, to prevent frost damage to the storage

tank, pipe system and connections.

NOTE

Install the storage tank as close as possible

to the heat generator, to keep the heat losses

as low as possible. Ensure the shortest pos-

sible pipe lengths to the load.

IMPORTANT

The floor or ground at the place of installation

must be dry, firm and able to safely support

the weight of the tank.

In the case of wall-mounted storage tanks,

the wall must have sufficient load-bearing ca-

pacity to safely carry the weight of the stor-

age tank when full.

"Technical Data“, from page 9, for the respec-

tive model

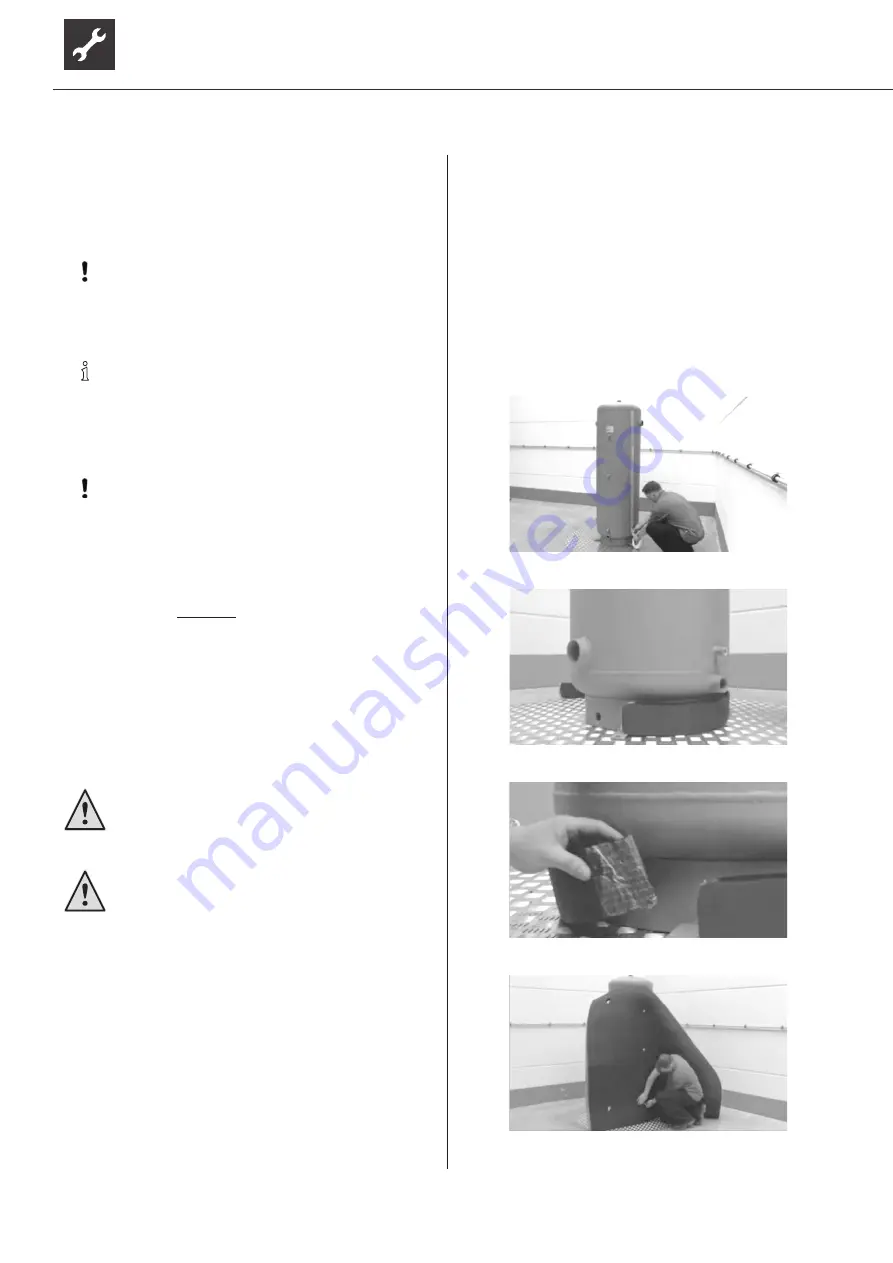

10.1 Transport to installation location

To avoid damage during transport, transport the

storage tank (secured on the wooden pallet) to its final

installation location using a lifting truck.

WARNING

Make sure to secure tank against slipping

during transport.

WARNING

The tank can tip over when being removed

from the wooden pallet and during

transport with a hand truck or lifting

truck. This can result in personal injuries

and damage.

► Take suitable precautions, which prevent

the tipping hazard.

► Dispose of the transport and packaging materials

properly and under ecological aspects.

10.2 Installation

When installing the tank, ensure sufficient clearance

from walls and other objects to enable the connection

pipes to be fitted.

10.3 Assembly

Cold insulation

Only TPSK 1000 and TPSK 1500

1. Attach adhesive tape such that the start and end

of the insulating jacket come together at the adhe-

sive tape. (Note connections).

2. Insulate base.

3. Connect insulation to the adhesive surfaces.

4. Start with the insulation on the connections.