Aisino RCK-600 User Guide

CHATPER 5 TROUBLESHOOTING

5.1 Warning Messages and

Troubleshooting

This printer is designed for minimal user intervention. Occasionally, the LCD displays

messages to advise users to take corrective actions.

After clearing an

error, press SET to initialize the printer and [Ready] will be displayed

.

•

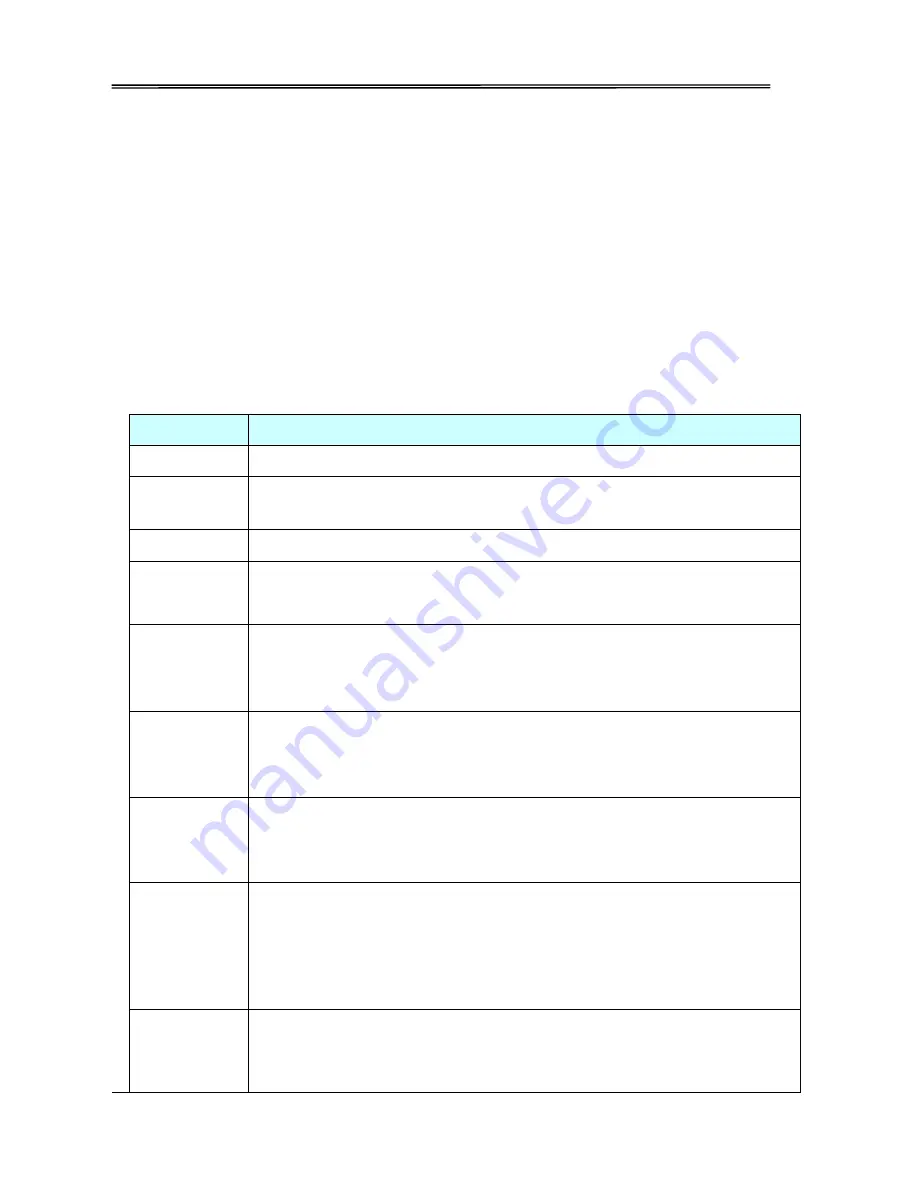

Warning/Error

List

Display

Solution

Press

SET Key

Push the

SET Key

once

Feeder empty

Card cassette is empty. Refill cards to the feeder. Press

SET Key

to resume

printing.

Cover Open

Close the front cover tightly

Temp

Disorder

Ensure the printer is operating at the specified ambient temperature. Then

restart the printer

Check

Ribbon/Film

Cause: The unused ribbon/retransfer ribbon reached the levels set in

“Ribbon Near End”

or

“RTM Near End”.

Action: Beware if unused ribbon/retransfer film is sufficient for your print job.

Ribbon End

Do not turn off power. Refer to Section 2.2 to replace a new ribbon. Press

SET Key

to clear this warning and the printer

resumes the previous printing

after initialization.

Film End

Do not turn off power. Refer to Section 2.3 to replace a new retransfer film.

Press

SET Key

to clear this warning and the printer will resume previous

printing after initialization.

Invalid

Ribbon

Probable Cause: Unrecognized ribbon.

Action: Do not turn off power.

Refer to Section 2.2 to reload the ribbon if

ribbon is

skewed. Or, check if ribbon type is YMCK/YMCKK. Press

SET Key

to

clear this warning and the printer will resume previous

printing after

initialization.

Invalid Film

Do not turn off power. Open the front cover to check if any abnormality

withe retransfer film. Correct the fault and close the top cover. Press

SET Key

to clear this warning and the printer resumes the previous printing after

75