12

INSTALLATION

INSTRUCTIONS

SDN2 • SDN3

WARNING!

Installation of this appliance must be made in accordance with the

written instructions provided in this manual. No agent, representative or employee

of Suburban or other person has the authority to change, modify or waive any

provision of the instructions contained in this manual.

1.

In the U.S.A.,

the installation must conform with state or other codes or in the

absence of such codes, refer to the latest edition of:

a.

Standard for Recreational Vehicles NFPA 1192.

b.

National Fuel Gas Code ANSI Z223.1/NFPA 54

In Canada,

the installation must be in accordance with:

a.

Standard CAN/CSA 240.4.2-08, Installation Requirements for Propane

Appliances and Equipment in Recreational Vehicles.

b.

Any applicable local codes and regulations

2.

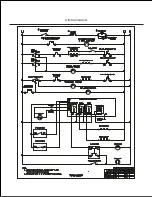

Minimum clearances from combustible walls above and below counter:

MODELS

Below Counter

Center of Burner Head(s) to adjacent vertical

combustible material above the cooking

surface burners.

Sides, Rear

and Bottom

Right

Sidewall

Left

Sidewall

Backwall

SDN2

0”

5 7/8”

5 7/8”

8”

SDN3

0”

5 5/8”

6”

8”

3.

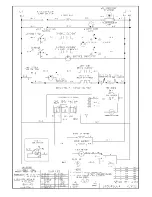

Cut-out dimensions illustrated in Figure 2 are as follows:

MODEL

DIMENSIONS

A

B

C*

D*

E

SDN2

16 3/8”

11 5/8”

2 3/16”

3/4” min.

18”

SDN3

18 15/16”

16 1/8”

2 1/16”

2 3/8” min.

21”

*Minimum acceptable spacing between adjacent models is 3 inches.

WARNING!

Installation of cook top cannot be such that the user is required to reach over any

of the burners to reach the knobs.

4.

Before placing drop-in cook top into cabinet, determine which one of the three

knockout openings in the burner box (left side, right side or rear) will be used for

routing of the gas supply tubing to the pressure regulator. After making selection,

knockout the 1 inch plug. Place drop-in cook top into the prepared opening and

secure to cabinet with four (4) wood screws. (Not provided)

NOTE: For models with a manifold extension, place the drop-in cook top into

the prepared opening and secure to the cabinet with four (4) wood screws. (Not

provided)

5.

Route gas line through opening in burner box and connect the gas line to the 3/8”

flare fitting inside the burner box. Place nylon bushing over gas line and insert

bushing into opening in burner box.

NOTE: For models with a manifold extension, connect the gas line to the 3/8”

flare fitting just outside the burner box. Be sure to hold the fitting on the

extension with a wrench when tightening the flare nut. Failure to hold fitting

secure could result in a gas leak due to fitting being damaged.

CAUTION: Gas supply tubing within the confines of the appliance burner box

shall be rigid or semirigid metallic tubing.

6.

Be sure all openings in the cabinets around the gas line are sealed at time of

installation.

CAUTION:

It is imperative that the cabinet in which the cook top is placed be separated from

other appliances so that the combustion air supply to the top burners can not be affected in any

way by any forced-air heating appliance or its return air system or by any other source of positive

or negative air pressure. A negative air pressure created by another forced air appliance may

draw the flame down around the top burners and into the cook top resulting in damage to the

burners and cook top, as well as possible personal injury and/or damage to vehicle. A positive

draft could cause the burner flame to lift-off the burner and go out resulting in an uncontrolled

escape of gas. Whenever the gas fumes reach an open flame or another ignition source, an

explosion and/or fire will occur resulting in property damage, personal injury and/or loss of life.

7.

Be sure burner knobs are in “off” position. Turn on gas supply. Check all

connections for leaks.

WARNING!

Never check for leaks with an open flame. Apply a soap and water solution to all

joints to see if bubbles are formed.

NOTE:

The appliance must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in excess of 1/2 PSIG.

8.

Remove the top and the grate(s) from their packing - Install the grate(s) on the top.

9.

Position the top over the burners and secure in place with two (2) thumb screws

and two (2) nylon washers provided.

10.

Your Suburban Drop-in Cooktop is now ready for operation. Before operating,

read the safety information and operating instructions contained in the installation

manual.

11.

If installation of this product is in a portable counter top, the following additional

guidelines must be followed:

a.

Portable counter top is provided by installer and must be able to support a

minimum weight of 20 lbs.

b.

OEM must provide a label placed on the counter top that clearly states the

maximum weight that can be added to the portable counter top after installation.

(This should take into account the weight of the cooking unit - 20 lbs).

FOR EXAMPLE:

Mounting bracket used is rated for 100 lbs. OEM should weigh

fabricated counter top. Subtract weight of counter top (i.e. 20 lbs) and weight of

cooking unit (20 lbs.) from 100 lbs. The weight label should say no more than 60 lbs.

can be put on the counter top.

c.

The surface material for the counter top must be rated for a minimum of 200°F

continuous operation temperature with the maximum weight applied.

d.

Minimum clearances from combustible walls above and below the counter top

must be adhered to during operation.

e.

The OEM must provide a warning label placed on the counter top that requires

the unit to be cooled a minimum of 30 minutes after use before storing.

f.

During storage, a clearance of 1” must be maintained from the top surface of

the unit.

g. NOTE:

The gas must be turned “OFF” and disconnected when stored.

A

4"

3 1/8"

18"

E

MIN.

C

MINIMUM DISTANCE TO COMBUSTIBLE SURFACES

DIRECTLY ABOVE COOK-TOP 24"

*D

WALL

*C-SEE UL LABEL

*

13" MAXIMUM OVERHEAD

CABINET DEPTH

B

REAR

FRONT