airpower europe GmbH, Auf der Hohl 7, D-53547 Dattenberg,

www.airpower-gmbh.com

24

Note

During manual calibration, this

can

be aborted

by pressing the

A/M

key

and

switched to normal operation.

5.4 Diagnostic mode

5.4.1 Switching to Diagnostic Mode

In normal operation, press a/M

button

and

press for

at

least

3 seconds to switch to

diagnostic mode. The value of

the parameter is displayed in the upper row, and the name of the parameter is displayed in the lower row.

Press the button, the parameter

will scroll upwards.

Press the button, the parameter

will scroll down.

5.4.2 Exiting Diagnostic Mode

In diagnostic state, press A/M

key

for

3 seconds to exit diagnostic mode and return to normal operation.

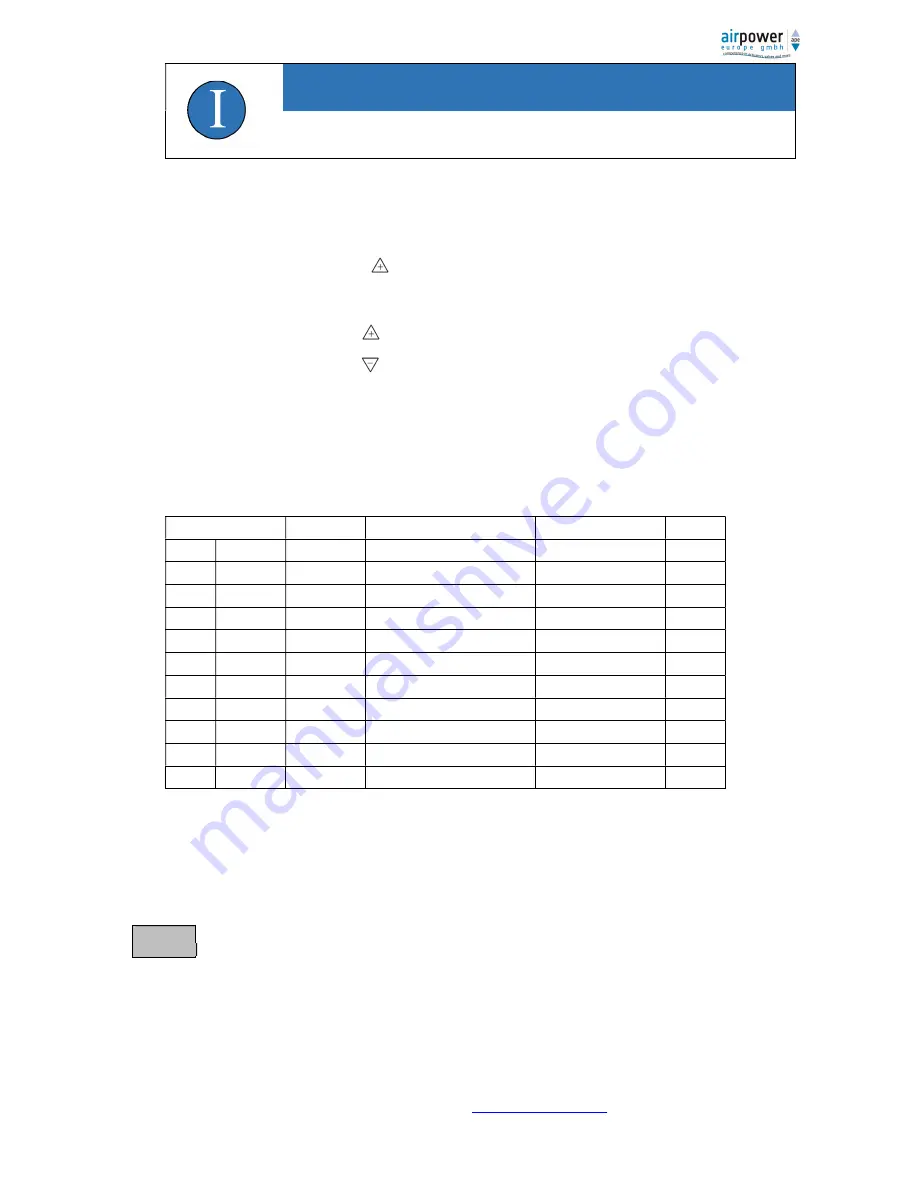

5.4.3 Diagnose-Parameter

Parameter

View

Function

Displayable values

Unit

01

CURR

#

CURR

Input current

4.00 to 20.00

mA

02

Tup

#

TUP

#

Travel time up

0 to 200

S

03

TDW

•

TDW

Travel time down

0 to 200

S

04

DBUP

#

DBUP

Dead band up

0.1 to 10.0

%

05

DBDW

#

DBDW

Dead band down

-0.1 to 10.0

%

06

PUP

#

PUP

#

Prediction up

1 to 100

%

07

PDW

#

PDW

#

Prediction down

1 to 100

%

08

IMUP

#

IMUP

Pulse length up

2 to 200

ms

09

IMDW

#

IMDW

Pulse length down

2 to 200

ms

10

SSUP

#

SSUP

Slow-moving-Zone up

0.1 to 100.0

%

11

SSDW

#

SSDW

Slow-moving-Zone down

0.1 to 100.0

%

5.5 Alarm

5.5.1 Zero point of position sensor too low

If the value for the adjusting adapter angle in the uninitialized state less than -52,0 is, the LCD display "DOWN":

Solution: Check that the installation of the adapter is

in accordance with

Chapter 4.2.

2

was made. Adjust the

mounting brackets / the adapter.

5.5.2 End point of the position sensor too high

If the feedback position in the non-initialized state is greater than 52.0, the LCD displays "UP":

DOWN

-53