5.Periodic inspection/Maintenance

5-10

5.5.6

Change compressor oil

At 300 hours for the first change and at every 500 hours thereafter

For prevention of fire caused due to deteriorated oil separator, in principle change of compressor

oil is to be performed in accordance with the schedule mentioned in the regular maintenance

table.

However, it is heavily influenced by operation conditions and environmental conditions. If it has

been found more dirty and corrupted, it should be changed.

If machine is continuously operated in such bad conditions, it could damage bearings and

degraded oil sticks oil separator to cause accumulated oxidation heat of reaction to lead oil

separator fire. For this reason, regular maintenance work should be done surely and perfectly.

Conduct changing compressor oil after checking machine stoppage for about 2-3 minutes and

dropping pressure of separator receiver tank to zero.

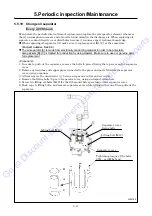

<Procedures>

1.

After the machine has stopped and pressure inside

the separator receiver tank has been completely

released as much time passed, remove the oil filler

cap [A] and open the drain valve [B] to drain the

residual oil. Further, open the drain valve [E] after

removing oil cooler drain plug [D] and drain the oil

accumulated in the cooler.

2.

After draining compressor oil, surely retighten drain

valve [B] and [E].

3.

Fill the tank with new compressor oil up to the height

indicated by the dotted line (Fuel Limit). Then, close

filler cap [A]. Inspect O-ring [C] of filler cap [A]. and

replace it with a new one if any hardening or damage

is found.

4.

After starting operation, check and confirm that oil

level is within red lines of oil revel gauge.

5.

Repeat the process 1

to 4 if oil level is out of red lines

range.

Mixture of different brands compressor oil could cause an increase of viscosity and

make compressor oil sticky. In the worst case, it could cause sticking trouble of

compressor air-end “Compressor air-end will not turn”. Also repairing of such air-end

needs expensive cost. Therefore, be sure to avoid mixing different brands oil. In case

compressor oil brand in use has to be unavoidably changed, it is absolutely necessary

to completely clean up the interior of compressor air-end. In such a case, contact

“AIRMAN” dealer or us directly.

Follow the designated regulations to dispose of compressor oil.

CLOSE OPEN

A180277

Quantity of oil between the red lines

Approx.5L

Quantity of change oil

Approx.40L

A

C

B

E D

Red

lines

Drain

container

Fuel Limit

Go

to

Discount-Equipment.com

to

order

your

parts