3.Operation

3-7

3.3.3

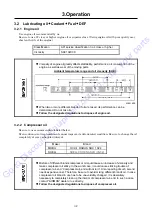

Check compressor oil level

Place the machine on level ground when checking the

oil level.

After checking and confirming that the residual

pressure in separator receiver tank is

0PSI

,

replenish the tank with compressor oil so that the oil

level is kept higher than the Lower limit of level

gauge plate. Be sure to check the surface of

compressor oil is in the range between upper limit

and lower limit when machine operating.

(See 5.5.6)

※

Supply of excessive oil can cause deterioration of oil

separation performance and the like.

When you fill the separator receiver tank with

compressor oil, stop the engine, and make sure that

the pressure gauge indicates

0PSI

and there is no

residual pressure in it, and then gradually loosen the

oil filler cap for refilling oil.

Should any residual pressure be left in the separator

receiver tank, hot compressed air and hot

compressor oil jetting out could cause burning or

serious injury to persons nearby.

3.3.4

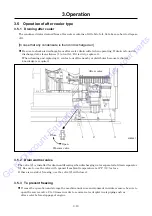

Drain separator receiver tank

Gradually opening the drain valve [2] fitted under

the separator receiver tank [1] as shown in the fig,

drain the condensate.

Be careful not to fully open the drain valve.

Otherwise, much oil may be lost.

After draining the oil completely, close the drain

valve firmly.

Drain the condensate in container [3], and then

dispose of condensate according to the designated

regulations.

Touch the fluid and check its viscosity to determine

whether it is condensate or compressor oil, and when it

is difficult to distinguish between the two.

After stopping the engine, confirm that the pressure

gauge indicates

0PSI

and there is no residual

pressure in it, then open the drain valve gradually to

drain the compressor oil.

Note residual pressure in the receiver tank could

force both extremely hot compressed air and oil to jet

out and you may be scalded or seriously injured.

A160696

Upper limit

Lower limit

Separator

Receiver tank

W010

A160697

H990432

1

2

3

CLOSE OPEN

Go

to

Discount-Equipment.com

to

order

your

parts