23

1.800.627.4499

SA-Series

CORE ARRAY

INSTALLATION

6.0 DUCTWORK

6.1 AIR PRESSURE MONITORS

It is the installer’s responsibility to provide and install all ductwork.

Provision must be made

for annual access to the inlet side of all cores for vacuuming. Access must permit a

worker to go into the plenums.

All ductwork is to be fabricated and installed in accordance

with SMACNA guidelines.

RenewAire suggests that all plenums or their ducts be labeled to indicate which ones are for

entering air, and therefore require annual servicing.

RenewAire does not make any recommendations regarding installation of air pressure/air quality

monitors.

www.renewaire.com (800) 627- 4499

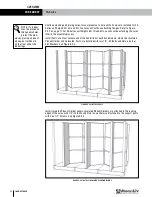

Install roof panels using #8 x 1/2" Screws. See Figure 5.4.10.

Use silicone caulk on all seams.

FIGURE 5.4.10 INSTALL ROOF ASSEMBLIES

7.0 MAINTENANCE

There are only two maintenance issues that are of concern. The first is that clean air filters are

always in place, whether the unit is being operated or not. Even if there is no airflow through

the unit, filters must be kept in place to avoid dust, dirt and debris from entering the structure.

A need for filter changes is generally discovered by an automated monitoring system that is part

of either a Direct Digital Controller (DDC) or a Building Management System (BMS). If there is

no pressure drop data that can be used to indicate dirty filters, the filters should be inspected

monthly. If filters look dirty, replace them! Scheduling of filter replacement is part of the facility

maintenance program and filter replacement records should be maintained elsewhere.

The second issue is annual vacuuming of the face of the enthalpic cores. The leading surfaces

of the cores that are exposed to an incoming airstream must be vacuumed annually. This

applies only to the inlet side of the cores, not the outlet side. Any dirt buildup that occurs on the

cores will be in the front 1"–2" of the leading surface. Careful vacuuming with a powerful shop

vacuum, using a head with soft bristles, will normally remove the dust and dirt that otherwise

reduce airflow and efficiency. Do not use compressed air on the cores nor any liquids.

DO NOT USE FILTER SPRAYS ON THE FILTERS.

Oily residue can migrate to the cores,

permanently reducing their efficiency.