Performing quality control (QC) tests

The following procedures must be performed daily, weekly or annually as

indicated. When used in a mobile application it is required to do a QC after

every move.

The reason for performing quality control tests is to determine if any

significant image quality variation or deterioration has occurred which may

require corrective action. Comparing the results of the tests with the reference

values previously established does this.

This procedure allows the operator to take the necessary preventive actions

before any image quality loss can take place.

Topics:

•

•

Performing the weekly QC tests

•

Performing the annual QC tests

Performing the daily QC test

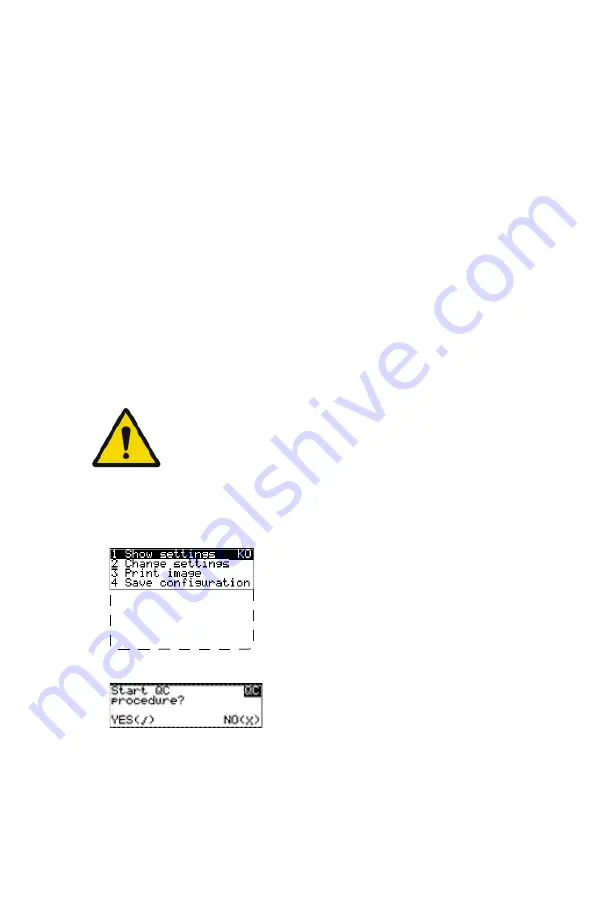

WARNING:

This test must be performed every day before any clinical film

can be processed.

1.

Turn on the printer and wait at least for 15 minutes.

2.

Press the Key-operator key to enter the Key-operator mode.

3.

Press the down key seven times, followed by the ok key to select ‘QC’.

5 Restore config.

6 Calibration

7 Service Actions

8 Quality Control

9 Installation

Reachable with Up/Down arrow keys

Visible

A confirmation screen appears:

4.

Do one of the following:

• Press the Confirm key (YES) to start the QC procedure and proceed

with step 5.

• Press the Escape key (NO) to quit.

5.

Define the tray for printing.

The ‘Select tray’ screen appears:

102

| DRY 1.4, DRY 2.4 | Advanced Operation (key-operator mode)

3631B EN 20210601 1655

Summary of Contents for 5366/500

Page 1: ...DRY 1 4 DRY 2 4 5366 510 5366 500 User Manual 3631B EN 20210601 1655 ...

Page 12: ...12 DRY 1 4 DRY 2 4 DRY 1 4 DRY 2 4 3631B EN 20210601 1655 ...

Page 57: ... The display DRY 1 4 DRY 2 4 Introduction 57 3631B EN 20210601 1655 ...

Page 141: ...DRY 1 4 DRY 2 4 Plug Play Installation Manual 141 3631B EN 20210601 1655 ...