– English –

Decommissioning, disposal

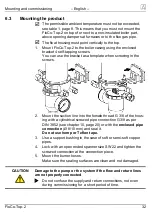

FloCo-Top-2

39

Problem

Possible reason

Repair

Oil cannot be

sucked in or steady

flow keeps being

interrupted

Small leaks at the screw

connections between the

withdrawal fitting at the

tank and the burner allow

air to get into the suction

line. This is also the case

during idle times until the

vacuum no longer exists.

This generates an air cush-

ion in the suction line

Use cylindrical screwed pipe

connections at the housing

and seal them with flat cop-

per gaskets (air-tight). Use a

support bushing

in the

case of soft or semi-soft

copper pipes. Check all seal-

ing surfaces for damage.

Close the stop valve at the

withdrawal fitting and per-

form a vacuum test (at least

-0.6 bar) at the supply con-

nection of the oil vent.

Burner pump does not

generate a sufficient vacu-

um

Perform a suction test at the

pump. The pump must gen-

erate a vacuum of at least

-0.4 bar.

After a filter or burner hose

replacement, the drain

valve or the bypass valve

have not been closed after

draining

Close valves

Other malfunctions

–

Send the product to the

manufacturer

10 Decommissioning, disposal

1.

Dismount FloCo-Top-2 (see chapter 6.3, page 13, reverse se-

quence of steps).

2.

To protect the environment, this product must

not

be disposed

of together with the normal household waste. Dispose of the

product according to according to local directives and guide-

lines.

This product consists of materials that can be reused by recycling

firms.