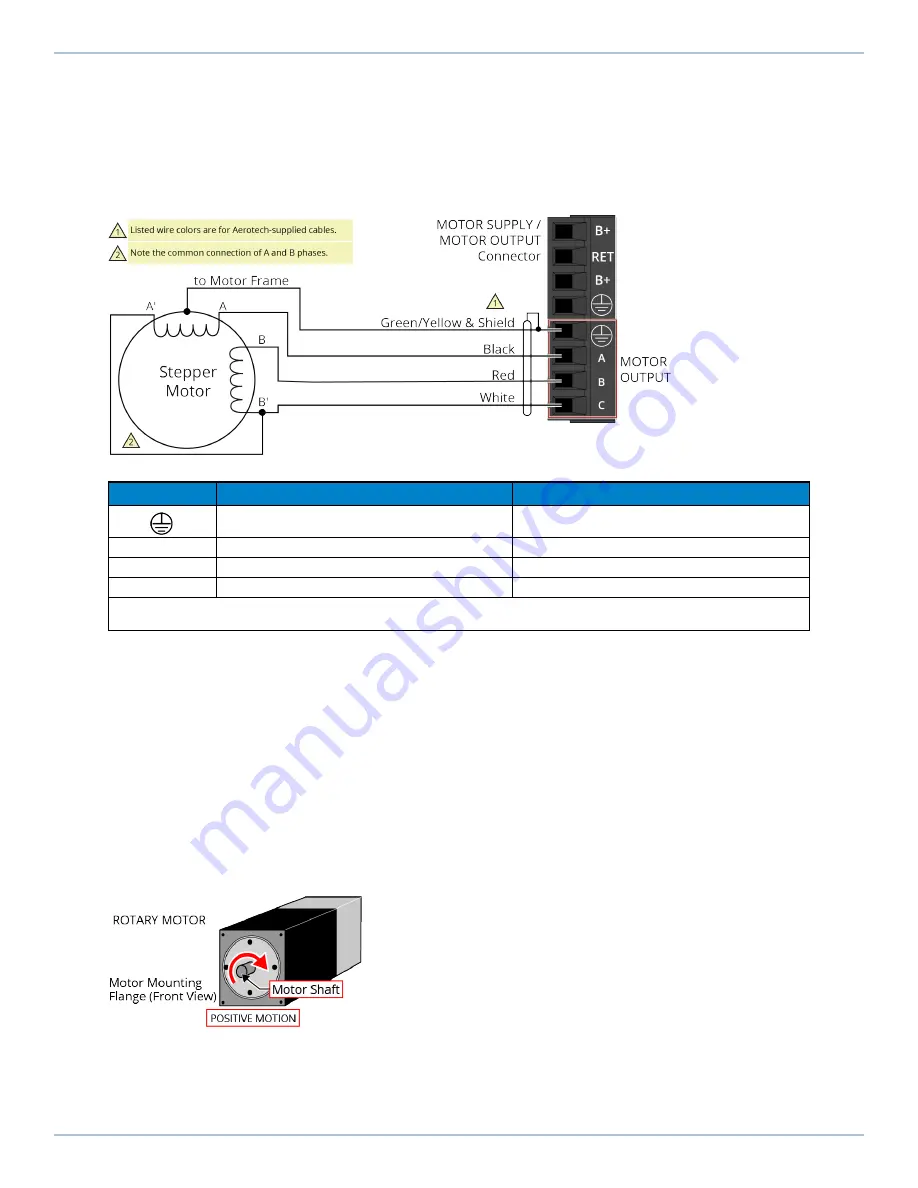

2.2.3. Stepper Motor Connections

The configuration shown in

is an example of a typical stepper motor connection. Refer to

for information on motor phasing.

In this case, the effective motor voltage is half of the applied bus voltage. For example, an 80 V motor

bus supply is needed to get 40 V across the motor.

Figure 2-10:

Stepper Motor Configuration

Table 2-10:

Wire Colors for Aerotech-Supplied Stepper Motor Cables

Pin

Wire Color Set 1

(1)

Wire Color Set 2

Green/Yellow & Shield

(2)

Green/Yellow & Shield

A

Black

Brown

B

Red

Yellow

C

White

White & Red

(1) Wire Color Set #1 is the typical wire set used by Aerotech.

(2) “&” (Red & Orange) indicates two wires; “ / ” (Green/White) indicates a single wire.

2.2.3.1. Stepper Motor Phasing

A stepper motor can be run with or without an encoder.

Without an Encoder:

You do not need to phase the motor.

With an Encoder:

Because the end of travel (EOT) limit inputs are relative to motor rotation, it is

important to phase the motor.

Run a positive motion command. The motor is phased correctly if there is a positive scaling factor

(determined by the CountsPerUnit parameters) and the motor moves in a clockwise direction when

you view the motor from the front mounting flange (

). If the motor moves in a

counterclockwise direction, swap the motor leads and re-run the command. After the motor has

been phased, if you want to change the direction of positive motion, use the ReverseMotionDirection

parameter.

Figure 2-11:

Positive Motor Direction

For Aerotech-supplied systems, the motor, encoder and Hall sensors are correctly configured and

connection adjustments are not necessary.

2.2.3. Stepper Motor Connections

XL2e Hardware Manual

34

www.aerotech.com