Glycol Chillers : BC Series with MG Control Instrument

Page: 62

ADVANTAGE ENGINEERING, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-0729 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Email: [email protected]

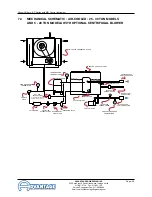

6.1 WATER SYSTEM

A.

MOTOR/PUMP ASSEMBLY: The motor/pump

assembly circulates chilled fluid to the process loop.

The pump assembly is built of total stainless steel to

maintain water quality.

B.

RESERVOIR. The vented reservoir is sized for the

chiller application to support the flow rate. The reservoir

provides a stable water temperature under varying load

conditions.

6.2 REFRIGERATION SYSTEM

A.

COMPRESSOR: Compressors take low pressure/low

temperature refrigerant gas and compress the gas into

high pressure/high temperature gas.

B.

AIR COOLED CONDENSER: The air cooled

condenser removes heat from the compressed

refrigerant gas. The action causes the gas to

“condense” into a liquid state still under high pressure.

Air flow across the condenser is achieved via a motor

driven fan assembly or centrifugal blower.

C.

WATER COOLED CONDENSER: The water cooled

condenser removes heat from the compressed

refrigerant gas. As the heat is removed, the gas

“condenses” into a liquid state, still under high

pressure. Water regulator valves are used on all

models to control the refrigerant head pressure by

modulating the condenser water flow.

D.

FILTER-DRIER: The filter-drier removes contaminants

and moisture from the liquid refrigerant.

E.

REFRIGERANT SIGHT GLASS: The refrigerant

sight glass indicates refrigerant charge and moisture

content.

• Full refrigerant charge is determined by a

clear liquid flow.

• Bubbles indicate low refrigerant.

• Moisture content is indicated by the color of

the element.

• Element color is normally green.

Typical Filter Drier

Typical Air-Cooled Condenser

Reservoir

Compressor

Coolant Pump

Typical Water-Cooled Condenser