1314-900 Revision BA

250W Precision Calorimeter

22

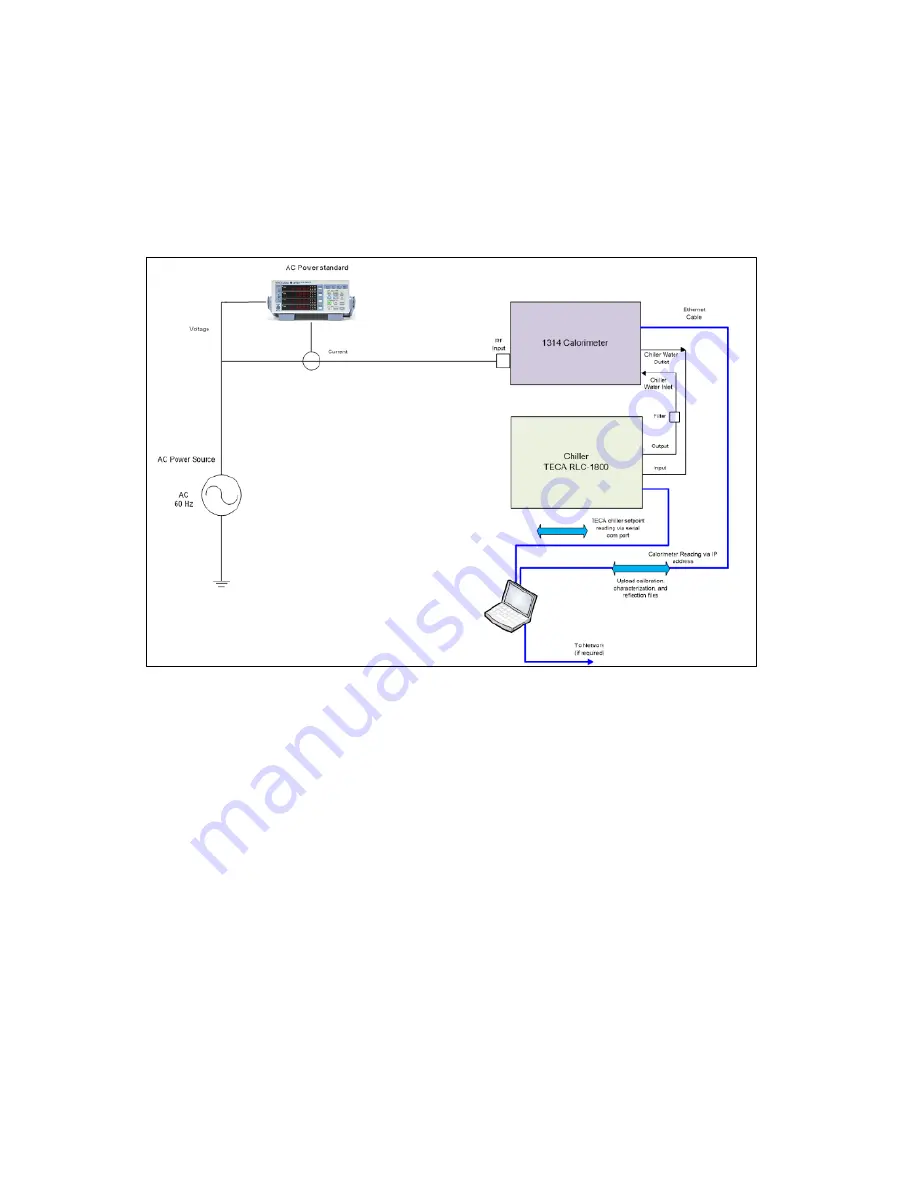

Manual AC Calibration Procedure

To calibrate a RF device using the 250 watt calorimeter, the calorimeter must first be calibrated

against an AC power meter standard traceable to a governing authority i.e. NIST, etc. Configure

the equipment setup as shown in Figure 17. Set the 1314 to read AC power by pressing the

AC/RF soft key on the front panel display to AC.

After confirming fluid is flowing properly in the calorimeter and the correct chiller set point has

been entered, slowly apply AC power monitoring the total output power as read by the externally

supplied AC power meter standard. When the desired calibration power level has been reached,

continue to keep the power constant and allow the calorimeter to settle for >~ 6 minutes and then

read the AC value in the front panel display. Repeat this process for as many power level points

as desired for testing. When finished, shut off the AC source power to the input of the calorimeter

and allow the coolant fluid to continue flowing through the load for a minimum of >3 minutes

before shutting down the chiller supplying the coolant flow. At this point, you will have a table

consisting of AC power applied versus AC power as read by the calorimeter. These points can

then be manually input into the excel spreadsheet titled “1314 annual Calibration best fit

algorithm” to generate the slopes (m’s) and intercepts (b’s) of the resulting piecewise linear

approximation to the relationship between these two variables. Once these sets of m’s and b’s are

collected for each power level, they can be transferred to the file titled “calibration.ini”. This file

is then uploaded using the Iguana Manager to the 1314 and stored in its local memory. The

calorimeter is now fully calibrated to proceed forward with RF input measurements.

Figure 17: Manual AC Calibration Configuration