ENGLISH (translation of original instructions)

The pumps described in this manual, once you have unpacked and inserted them in a pumping system, are

machines that can fill a receiving tank with diesel fuel sucked from a gravity storage tank.

2 - MACHINE SPECIFICATIONS

2.1 - I

ntended

use

1 - GENERAL WARNINGS

2.2 - d

escrIptIon

of

the

machIne

The pump is made up of the following parts:

PUMP :

volumetric self-priming rotary eccentric barrel electric pump fitted with a bypass valve.

MOTOR :

single-phase motor or 12V or 24V DC motor, brushed, closed (protection class IP55 in

compliance with Standard EN60034-5-86), directly flanged to the pump body.

TABLE OF CONTENTS

1 - GENERAL WARNINGS

2 - MACHINE SPECIFICATIONS

2.1 Intended use

2.2 Description of the machine

2.3 Technical specifications

3 - OPERATING CONDITIONS

3.1 Environmental conditions

3.2 Power supply

3.3 Allowed fluids / Forbidden fluids

4 - TRANSPORT AND HANDLING

4.1 Transport

4.2 Unpacking

4.3 Storage

5 - INSTALLATION

5.1 Preliminary checks and positioning the

pump

5.2 Hydraulic pipe connection

5.3 Remarks on the suction and discharge

lines

5.4 Electrical connection of the pump

6 - INTENDED USE

6.1 Preliminary checks and start-up

6.2 Daily use

6.3 Noise level

6.4 Compatibility in an electromagnetic

environment

7 - TROUBLESHOOTING

8 - MAINTENANCE

9 - DEMOLITION AND DISPOSAL

10 - WARRANTY

11 - TECHNICAL SUPPORT

12 - ATTACHMENTS

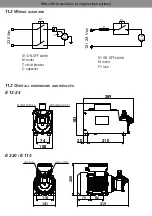

12.1 Exploded views and spare parts list

12.2 Wiring diagrams

12.3 Overall dimensions and weights

IMPORTANT: It is essential to have understood the entire instruction manual

before performing any operation, so as to safeguard operator safety and to avoid

potential product damage.

Storing the manual:

This manual must be kept intact and fully legible. The end user and the skilled technicians authorised with

installation and maintenance of the product in question must be able to consult it at all times.

Reproduction rights:

This manual is the property of ADAM PUMPS S.p.A., which is the sole owner of all rights provided for by

applicable law, including without limitation copyright rules. All rights under these rules belong to ADAM

PUMPS S.p.A.: reproduction, even partial, of this manual, its publication, modification, transcription, public

disclosure, distribution, marketing in any form, translation and/or development, loan, or any other activity

reserved by law to ADAM PUMPS S.p.A.