А1270 Electro-Magnetic Ultrasonic Thickness Gauge

Operation Manual

24

ACOUSTIC

CONTROL

SYSTEMS

2.3.2.2 Probe option

- Enters the library with transducers.

Active keys:

F1 (Test): starts the testing procedure of EMAT adjustment of the instrument to the selected transducer;

F3 (Open) or

: enters the library with transducers.

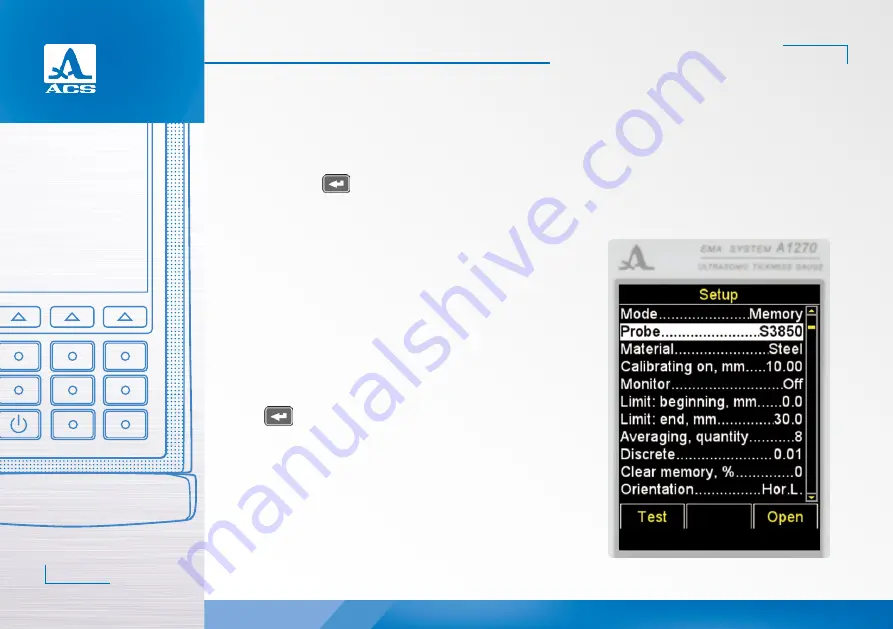

The Probe option is shown on the screen, Figure 20.

- Viewing the library with transducers.

The window header will show information on the currently used EMAT

“Current probe:”.

ATTENTION:

USERS MAY NOT ADD THE TRANSDUCERS (PROBES) TO THE

LIBRARY AND EDIT THE LIBRARY INDEPENDENTLY!

Active keys:

F1 (Test): starts the procedure of adjustment of the EMAT individual pa-

rameters.

F2 (View): provides viewing of the detailed information on a transducer.

The name, type and frequency of the EMAT is displayed on the screen.

F3 (Exit): returns to the main window of the SETUP mode.

selects the transducer from the list. The testing procedure of

EMAT adjustment to the parameters of the instrument will be started auto-

matically. The detailed description of the procedure is given in the paragraph

2.2.3.2.

Upon exiting the library, the instrument will remember the last active line

and will set it upon the next library entry. Upon switching Off the instrument

information on the active line of the library will be set to zero.

Figure 21: the screen of the instrument when viewing the library with

transducers.

Figure 20

2