13.9

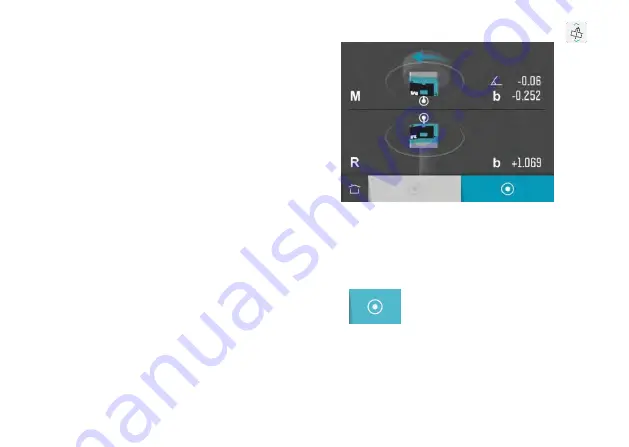

The screen displays the SR sensor at the

bottom and the SM sensor at the top.

The measurement is carried out by register

values in four positions, 0°, 90°, 180° and

270°. Index from CNC control or fixture is

needed. The graphics show where to rotate

the sensors.

When the SR sensor is positioned, the SM

sensor is positioned with the help of a relative

rotational angle. The rotational angle is shown

when the laser from the SM sensor hits the

detector of the SR sensor.

NOTE: The relative rotational angle must be

inside 0.1° at each position in order to get a

good result.

Set the SR sensor at the first measurement

position.

Set the SM sensor at the first measurement

position, with the help of the relative angle.

Touch the measurement icon.

This registers the first

measurement position.

Summary of Contents for Meax DU 01

Page 1: ...USER MANUAL MEAX...

Page 2: ......

Page 4: ......

Page 8: ...1 4...

Page 19: ...4 3 Do not use paper tissue which can scratch the detector surface Do not use acetone...

Page 20: ...4 4...

Page 24: ...5 4...

Page 56: ...7 12 Save the measurement result Go to adjustment...

Page 60: ...7 16...

Page 76: ...8 16...

Page 79: ...9 3 STARTING THE PROGRAM Start the Squareness program by touching its icon in the Home Menu...

Page 83: ...9 7 Confirm configuration Confirm configuration and continue to summary screen...

Page 104: ...10 10 Go to adjustment...

Page 108: ...10 14...

Page 122: ...11 14...

Page 132: ...12 10 Coaxiality Go to distance Measure and enter distance between the sensors SR and SM...

Page 140: ...12 18...

Page 148: ...13 8 Coaxiality Go to distance Measure and enter distance between the sensors SR and SM...

Page 155: ...13 15 Global Settings Open Global Settings Return Return to the program...

Page 156: ...13 16...

Page 160: ...14 4 Zero values Halve values Reset values to raw data...

Page 161: ...14 5 Sample and display a single value Return to live values...

Page 174: ...17 4 ZERO VALUES Measure max min Reset values to raw data...

Page 187: ...19 9 Level screen Switch to Straightness page...

Page 200: ...19 22...

Page 220: ...22 6...

Page 226: ...23 6...

Page 228: ...24 2...

Page 232: ...25 4...

Page 237: ...26 5 MAGNETIC BASE Pointing fixture and magnetic base...

Page 242: ...27 4...

Page 252: ...30 2...

Page 253: ......