55

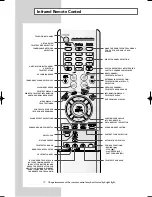

Module Assembly Key Point – Mechanical

1. Appearance Case assembly concern

1.1 Lower Case module

Label

Adjust Foot x1

(Free drop)

Push button

Spring

Mold in nut*3

Adjust Foot x2

(thread)

Add glue on thread

foot

Sub_Assy M4 Heat

melt nut*2

Sub_Assy M2.5 Heat

melt nut*3

Stand off*2

Sub_Assy M3 Heat

melt nut*2

Sponge adjust

Sponge Align the boss

M3 Screw

SATURN Adjust Foot(raer):

Follow MP5 Assembly Concept

Summary of Contents for S5201M Series

Page 17: ...17 System Block Diagram ...

Page 18: ...18 Product Overview ...

Page 19: ...19 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 47: ...47 Fig 3 4 Fig 3 5 Fig 3 6 Fig 3 7 Fig 3 8 Clip UP CM Sponge AL Screw MYLAR CM ...

Page 59: ...59 Inlet Case Module Fan FAN60 60 13 fan wire direction Outlet Case Module ...

Page 68: ...68 Attach mylar on UC align this edge First Second M3 screw ...

Page 70: ...70 9 Overall wire review Notice lamp wire dressing ...

Page 87: ...87 Chapter 5 FRU List Exploded Diagram Module 1 Total Exploded View ...

Page 88: ...88 ...

Page 89: ...89 Module 2 ASSY UPPER CASE ...

Page 90: ...90 Module 3 ASSY LOWER CASE ...

Page 91: ...91 Module 4 ASSY FRONT CASE ...