Page 5

©2005 Accent Signage Systems, Inc. All rights reserved.

TM

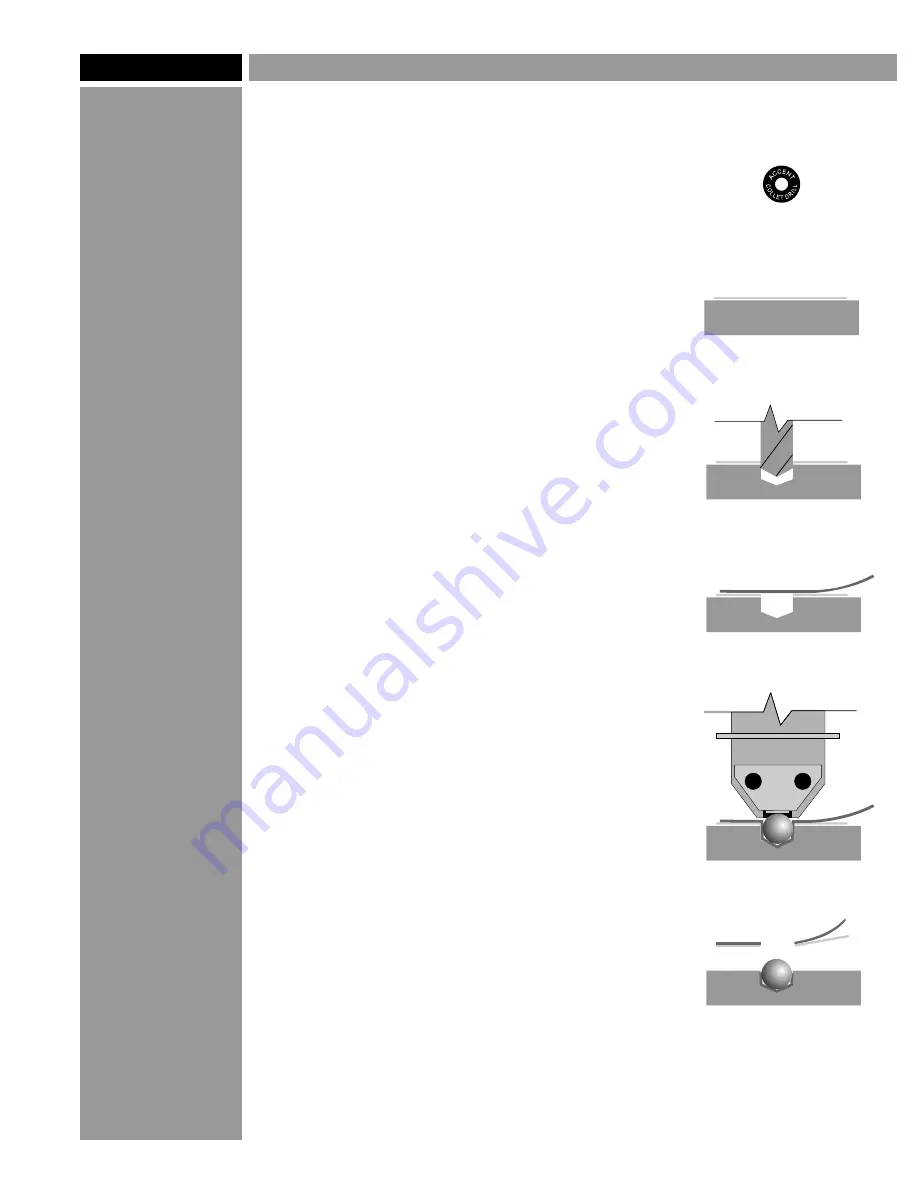

Raster Method of Braille

Adhesive-Assist Method

Use this method with metal substrates or

other materials that do not possess a

“memory,” such as solid-surface materials or

phenolic. It is also recommended for exterior

applications or materials that are to be plated

or anodized.

This method requires the collet assembly and

a carbide drill bit (black label), low-tack tape,

and double-sided adhesive tape. For best

results, use brass or stainless steel Rasters™

with the adhesive-assist method.

1. Apply a piece of low-tack tape to the sign

where the Braille message will be.

2. Set up and drill the holes for the Braille.

Drill directly through the tape to a depth of

about 0.045".

NOTE: Slow down the Z speed of your

engraver when working with metal. Your drill

bits will last longer drill cleaner holes.

3. Apply a piece of adhesive tape over the

holes. Before removing the tape's backing,

lightly “burnish” it down with your fingernail.

Remove the backing to expose the adhesive.

4. Using the Raster™ Pen, insert the

Rasters™ through the adhesive. Don't use too

much force; press only hard enough to seat

the Raster™ firmly in the sign.

5. Once all the Rasters™ are installed, slowly

peel off the low-tack tape. The excess

adhesive should come with it, requiring no

further clean-up. Peel the tape off carefully,

and avoid pulling it at a sharp angle.

6. Measure the height of the Rasters™ as

described on the previous page and adjust the

hole depth as needed.

Working with

Stainless Steel

Stainless steel is a

difficult material to

work with. It

requires precision

and patience. Drill

at very low RPM

and very slow

speed. Work

gradually down to

the proper depth;

don't try to do it all

at once. Drill

down a couple

thousandths, back

off, and drill

again, until you

reach the correct

depth.

We recommend

that you get

comfortable

working with

aluminum, brass,

and other softer

metals before

tackling stainless

steel.

Apply low-tack tape

Drill holes

THROUGH the

low-tack tape

Apply adhesive tape

Peel off low-tack tape

and excess adhesive

together

TM

Insert Rasters

through tape

Use collet assembly &

drill bit (black label)