Mounting and installation

42/14-36 EN

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

19

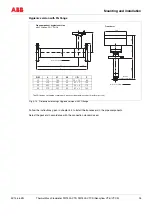

4.7.1

Technical data for integrated hot tap fittings

The hot tap fitting is designed for compressive loads of max. 16 bar. To ensure interchangeability with standard

pipe components (Design 1), the wafer flange version (Fig. 4-6) was developed for DIN flanges with a pressure

stage of PN 40. It is available in DN 50 and DN 80 formats for use with sensors with a length of 263 mm. For the

meter sizes DN 100, DN 150 and DN 200, use sensors with a length of 425 mm.

Fig. 4-5

Maximum pressure/temperature values for the integrated hot tap fitting

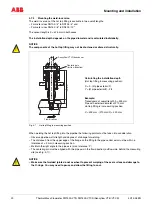

4.7.2

Mounting the wafer flange version

Fig. 4-6 (left) shows the wafer flange version of the hot tap fitting mounted in the pipeline in disassembly position,

i.e., the guide tube is in its upper end position and seals the Sensyflow opening (right).

The hot tap fitting is sealed on both sides with the flat gaskets against the mounting flange of the pipeline. For

greatest measurement accuracy, it must be centered exactly between the flanges, as it is for conventional pipe

components (see Fig. 4-1). Please observe the proper flow direction (arrow on pipe component).

Fig. 4-6

Hot tap fitting in disassembly position

Permissible pressure load

p_max. of the integrated hot tap fitting

0

2

4

6

8

10

12

14

16

18

0

50

100

150

200

250

T [°C]

p

[b

ar

]

Sensyflow-

opening

Temperature:

max. 200 °C

Pressure (abs.):

16 bar - 90 °C

1 bar - 200 °C