Mounting and installation

16

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

4.6

Weld-on adapter

4.6.1

Weld-on adapter for FMT400-VTS (Sensyflow VT-S) transducer

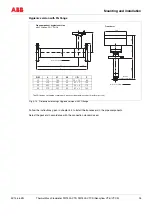

When installing the transducer in pipes with larger nominal width or non-round cross-section, the weld-on adapt-

er must be welded to the pipeline under consideration of the following information:

1.

The weld-on adapter must have a length L after welding (see Fig. 4-2 and Fig. 4-3)

L = h - ½

× ∅

D

outside

with h = 263, 425 or 775 mm (transducer lengths)

– The weld-on adapter must be shortened to the corresponding length before welding. After welding in

place, a few mm of the weld-on adapter can protrude into the pipe (max. 10 mm).

– Observe the pipeline wall thickness and amount of shrinkage when welding!

– The distance h from the flange top edge of the adapter to the pipe center line must be within a tolerance

of ± 2 mm.

2.

Rectangularity to the pipe axis must be absolutely kept (max. tolerance: 2°).

3.

The centering pin of the adapter must be aligned in flow direction to the pipe axis (at outlet run length, behind

measuring point).

4.

After welding the free passage for inserting the transducer must be at least 28 mm (if required, use drill to

clear).

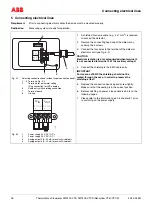

5.

Transducer installation:

– Insert the supplied O-ring (55 mm

×

3 mm) into the provided groove.

– Push the transducer into the adapter and screw together.

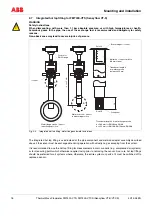

Weld-on adapter for FMT400-VTS (Sensyflow VT-S)

Fig. 4-2

Installation of the weld-adapter

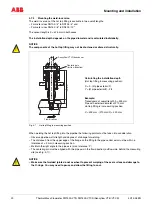

IMPORTANT

Deviations from the stated dimension and position tolerances cause additional measuring uncertainty.

Weld-on adapter

(upon delivery

Required accuracy of mounting

Centric mounting < ± 2 mm

Twist < ± 2°

* This maximum pipe diameter

specification is only valid when

installing the sensor centrically in

the pipe. For larger diameters or

angular ducts a non-centric

sensor position is taken into

account for calibration.

Length h

of the

transducer

(in mm)

Min./max.

outer pipe

diameter

(in mm)

263

100...350

425

> 350...700

775

> 700...1400

*

∅

d

∅

D

min. 28 mm

h

Z-189341

(1)

L

Direction of flow

Sealing ring groove

(1) Centering pin

on outlet side

∅

33,7

450 mm

Z-189342

(1)

Connection flange DN 25