Balancing

The motors rotor is dynamically balanced.

As standard, balancing has been carried out using half

key, and the shaft is marked with a RED tape, with the

text Balanced with half key. To avoid vibration, the

coupling-half or pulley must be balanced with a half key

after the keyway has been machined.

When balancing with full key, the shaft is marked with a

YELLOW tape, with the text Balanced with full key. To

avoid vibration, the coupling-half or pulley must be

balanced without a key after the keyway has been

machined.

In case of balancing without key, the shaft is marked

with a BLUE tape, with the text Balanced without key.

Special instructions for motors with a

frequency converter

ABB motors with protection types EEx d, EEx de, EEx e

(on request) and Ex nA/Ex N or EEx nA are certified for

use in variable speed drives.

The use of a motor with a frequency converter must be

studied in advance. Check that the motor fulfils the

specifications. The maximum loadability (T = f(N)) of the

motor and the type or characteristics of the converter

are shown by an additional rating plate or by a test

report delivered with the motor.

Flameproof motors EEx d(e) operating with a frequency

converter must be fitted with passive thermal protection

(thermistors, PT100). For non-sparking motors Ex nA/

Ex N or EEx nA such protection is recommended. The

converter must be capable of processing this informa-

tion.

Bearing currents with frequency converter

drives

The operation of a frequency converter induces addi-

tional high frequency shaft voltages, which can cause

sparking and high frequency current flow through the

motor bearings.

The motor cable must be symmetric and shielded. The

motor must be grounded and connected according to

the manual Grounding and cabling of the drive system.

The shield must be connected to both motor frame and

the inverter PE-terminal.

Bearing voltages and currents (sparks) must be avoided

in all Ex-motors. To prevent sparking and high fre-

quency bearing current flow inside the motor, a properly

dimensioned filter at the converter output is highly

recommended when nominal voltage is higher than

600V. Insulated bearings are fitted as listed below:

Sizes 280-400

Insulated bearing in the N-end (non-drive end).

The insulation method is indicated on the motor rating

plate, e.g. INSULATED BEARING IN N-END.

Connection

In frequency converter applications, motor frame exter-

nal earthing must be used for equalising the potential

between the motor frame and the driven machine,

unless the two machines are mounted on the same

metallic base. See manual Grounding and cabling of

the drive system.

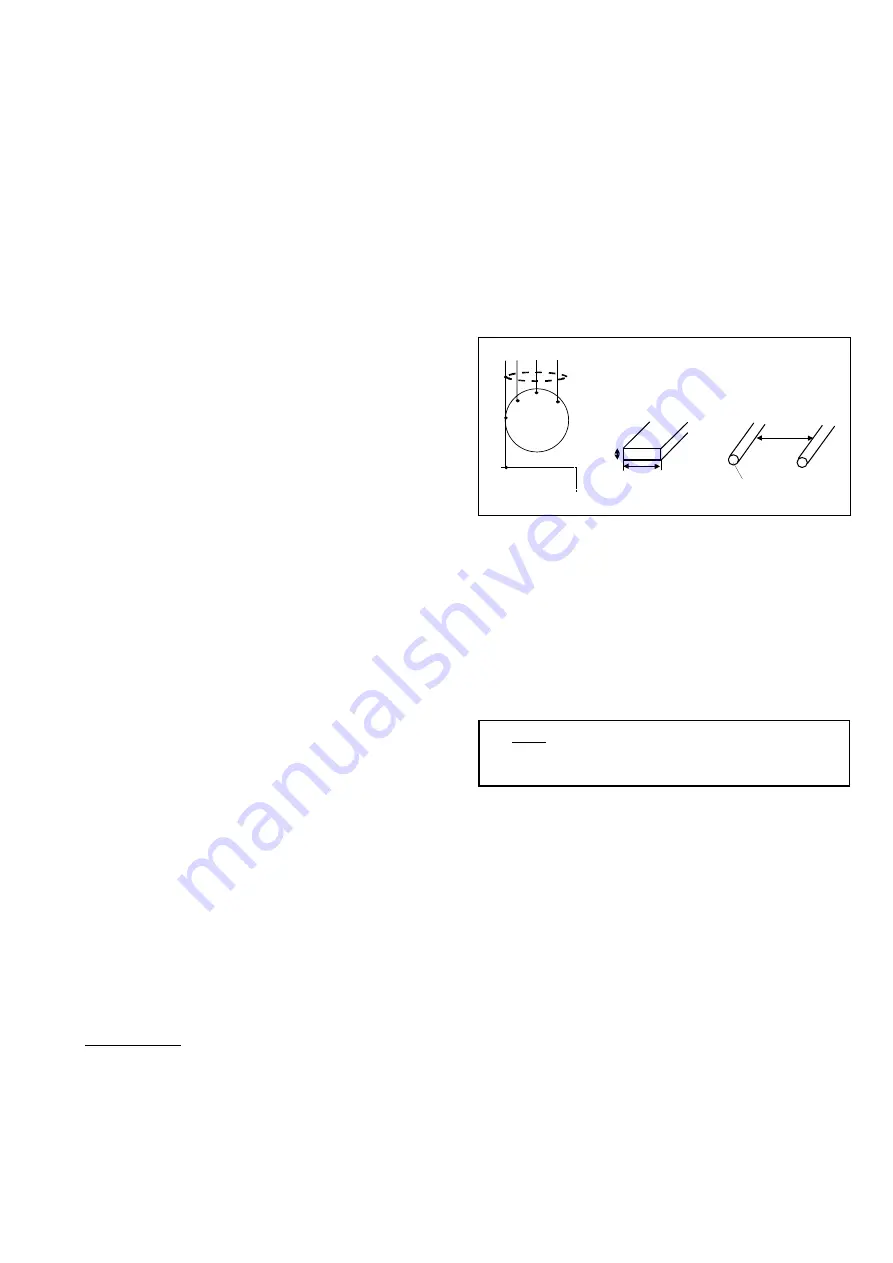

For motor frame sizes above IEC 280, use 0.75 x 70

mm flat conductor or at least 2 x 50 mm² round conduc-

tors. The distance of the round conductors must be at

least 150 mm from each other.

When the motor and the gearbox are mounted on a

common steel fundament, no potential equalisation is

needed.

To comply with EMC-requirements, use cables and

connectors approved for this purpose. (See instruction

for frequency converters).

NOTE: The oscillating frequencies of common mode

currents are very high, from 10 kHz to 1 MHz depending

on the actual drive set-up. Therefore, special attention

should be paid to the hf-impedance of the potential

equalising lead. A flat wound copper conductor or flat

copper bar is strongly recommended. The conductor

length should be as short as possible.

Note

For motors with a nominal voltage above 600 V,

du/dt filter or sinusoidal filter must be used.

Potential equalization

U1

V1

W1

PE

3 ~ M

Driven machinery

0.75 mm

70 mm

> 150 mm

min 50 mm

Cables/wires

Plate/strip