4 Repair

4.7.2. Replacement gearbox axis 2

3HAC026876-001 Revision: C

358

© Copyri

ght

200

6-2008 ABB.

All rights reserved.

7.

CAUTION!

The upper and lower arms (incl. gearboxes

axes 2 and 3) weighs 455 kg. All lifting

equipment used must be sized accordingly!

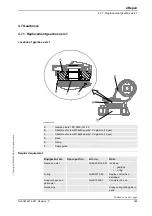

8. Fit the lifting tool on the upper and lower arms

and secure the robot in an overhead crane.

xx0700000350

Parts:

•

A: Lifting eye (on armhouse)

•

B: Lifting chain

•

C: Hoisting block

•

D: Lifting chain

•

E: Lifting chain

•

F: Roundsling (put in a loop

around the wrist on the inside)

•

G: Roundsling (put in a loop

around the lower arm)

9. Use a crank in the gearbox in order to find the

holes for the attachment screws.

10. Refit the lower arm to the gearbox axis 2 with its

attachment screws.

M16x60 (12 pcs)

Tightening torque: 300 Nm.

11. Refit motor axis 2.

12. Refit the lower end of the cable harness.

NOTE!

For Cleanroom robots the procedure is detailed

in section

.

cable harness, axes 1-6 on page 193

.

13. Fill the gearbox axis 2 with oil.

Action

Note

Continued

Continues on next page