3 Installation

6

INF09/027 Rev. D

| Endura AZ20 oxygen monitor | Pumped reference air unit

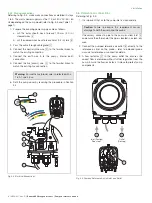

3.5.2 Making connections

Referring to Fig. 3.4, make mains connections as detailed in steps

1 to 5. The mains power supply must be 115 or 230 V AC, 50 / 60

Hz depending on the pump model (refer to Fig. 3.3 and Table 1.1,

1. Prepare the incoming power supply cable as follows:

a. cut the outer sheath back to leave 100 mm (4.0 in.)

sleeved wires

A

b. cut the sleeved wires back to leave 5 mm (0.2 in.) tails

B

2. Pass the cable through cable gland

C

.

3. Connect the neutral (blue wire

D

) to the terminal block to

match the existing connection.

4. Connect the earth wire E to the pump’s internal earth

connection.

5. Connect the live (brown) wire

F

to the terminal block to

match the existing live connection.

6. Refit the pump cover by reversing the procedure in Section

3.6 Reference air connections

Referring to Fig. 3.5:

1. It is important that air to the pump inlet is clean and dry.

If necessary, connect a pipe to the pump (suction) inlet

A

and ensure the other end of the pipe is located in a clean, dry

area.

2. Connect the pumped reference air outlet

B

directly to the

reference air inlet on the probe – refer to individual probe

manuals for reference air connection details.

3. A flow restrictor

C

in the pump outlet line ensures the

correct flow is delivered without further regulation from the

pump. Ensure the flow restrictor is in place to protect pump

components.

Warning.

Ensure the live (brown) wire is protected with a

1.6 A Type F fuse.

Fig. 3.4 Electrical Connections

B

F

A

C

E

D

Caution.

Failure to observe this requirement causes

damage to both the pump and the probe.

Fig. 3.5 Pumped Reference Air Unit Inlet and Outlet

A

B

C

Inlet (Suction)

See step 1

Outlet

(Delivery)