3 Installation

4

INF09/027 Rev. D

| Endura AZ20 oxygen monitor | Pumped reference air unit

3 Installation

3.1 Siting

Site the pump adjacent to the probe – see Fig. 3.1 for environmental

requirements.

3.2 Mounting

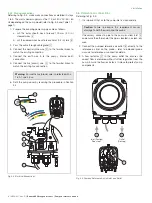

Overall dimensions are shown in Fig. 3.2. Mount the pump on a flat

secure surface using the 3 mounting lugs

A

.

3.3 Electrical safety

Fig. 3.1 Environmental Requirements

Dimensions in mm (in.)

Fig. 3.2 Dimensions and Mounting Lug Locations

IP66 (NEMA 4)

55 °C

(131 °F)

–20 °C

(–4 °F)

A

98

(3.9)

R3.2 (0.1

21

0 (8.3)

179 (7.0

)

150

(5.9)

71

(2.8)

Warning.

Isolate the incoming power supply before accessing the

pump or making connections.

The pump is not fitted with a switch therefore a

disconnecting device such as a switch or circuit breaker

conforming to local safety standards must be fitted to the

final installation. It must be fitted in close proximity to the

pump within easy reach of the operator and must be

marked clearly as the disconnection device for the pump.

Electrical installation and earthing (grounding) must be in

accordance with relevant national and local standards.

Use cable appropriate for the load currents: 3-core cable

rated 5A and 90 °C (194 °F) minimum, that conform to

either IEC 60227 or IEC 60245. The terminals accept

cables from 0.8 to 2.5 mm

2

(18 to 14 AWG).

The pump conforms to Installation Category II of IEC

61010.

After installation, there must be no access to live parts, for

example, terminals.

If the pump is used in a manner not specified by the

Company, the protection provided by the equipment may

be impaired.

All equipment connected to the pump's terminals must

comply with local safety standards (IEC 60950,

EN601010-1).

Caution.

Always route power cables and air lines separately.

Make connections only as shown.

Maintain Environmental Protection at all times.

Ensure the seal and mating surfaces are clean to maintain

environmental rating.

Conduit connections must provide cable entry sealing.

Ensure cable glands are tightened after wiring. Do not

overtighten the plastic cable glands to avoid destroying

their sealing properties. Initially, tighten finger-tight, then

a further

1

/

2

to

3

/

4

turn using a suitable spanner or wrench.

Fit a blanking plug where required.

Inductive loads must be suppressed or clamped to limit

voltage swings.