22

ABB IB 6.2.15.7-1C

G&T DEVICE

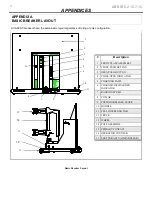

Part #

Qty/Device Description

14501G10

1

TRUCK ASSEMBLY (EXTENDED, 36” WIDE)

15011P00

15095P00

16965P00

16979P00

4

4

4

4

WHEEL

AXLE BUSHING

BOLT

LOCKNUT

14526G00

3

CABLE ASSEMBLY - LONG

14536G00

3

CABLE ASSEMBLY - SHORT

14540G00

3

POLE ASSEMBLY - 1200/2000A CONTINUOUS CURRENT; (ALL SHORT CIRCUIT CURRENTS

TO 50KA); INCLUDES PRIMARY DISCONNECTS AND MOUNTING HARDWARE

14547G00

3

POLE ASSEMBLY - 3000A CONTINUOUS CURRENT; (ALL SHORT CIRCUIT CURRENTS TO

50KA); INCLUDES PRIMARY DISCONNECTS AND MOUNTING HARDWARE

706741T13

6

PRIMARY DISCONNECT (“FINGERS”); 1200/2000A, TO 50KA SHORT CIRCUIT

706741T11

6

PRIMARY DISCONNECT (“FINGERS”); 3000A, TO 50KA SHORT CIRCUIT

G&T R

ENEWAL

P

ARTS

:

NOTE: The parts listed above are available from ABB for field use or replacement. Consult your ABB sales

representative for current pricing and availability.

The typical operating instructions as shown on the

instruction label attached to the front door of the

device is shown at the right. Renewal parts are

shown in the table at the bottom of this page.

CAUTION

(O

When moving or inserting the G&T

device, avoid exerting pressure on the

polyglass barriers. Damage to the

barriers may reduce dielectric strength of

the device.

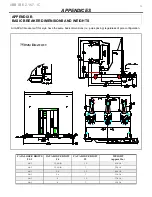

DESCRIPTION

WEIGHT

(

APPROXIMATE

LBS

)

1200/2000A G&T

175

3000A G&T

185

G&T D

EVICE

W

EIGHTS

:

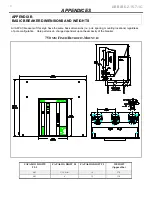

1.

THIS DEVICE IS FOR USE WITH CELLS DESIGNED FOR ADVAC MODEL AA1, AA2,

AND AA3 CIRCUIT BREAKERS. THIS DEVICE MUST NOT BE USED IN CELLS

RATED ABOVE THE NAMEPLATE RATINGS LOCATED ON THIS DEVICE.

2.

TWO (2) SETS OF CABLES ARE FURNISHED. THE SHORT SET ATTACHES TO

THE LOWER TERMINAL SET, AND THE LONG SET ATTACHES TO THE UPPER

TERMINAL SET.

3.

THIS DEVICE IS DESIGNED FOR USE WITH ONLY ONE SET OF CABLES AT-

TACHED TO A TERMINAL SET AT ANY GIVEN TIME. EITHER THE UPPER TERMI-

NALS ARE GROUNDED THROUGH THEIR CABLE SET OR THE LOWER TERMI-

NALS ARE GROUNDED THROUGH THEIR CABLE SET.

4.

A POSITION STOP IS PROVIDED IN THE CONNECT POSITION AND THE DISCON-

NECT POSITION. TO ASSURE THAT THE DEVICE IS IN THE FULLY CONNECTED

POSITION, THE “CONNECT” LABEL MUST BE IN THE CORRECT POSITION.

5.

THE DEVICE IS NOT DESIGNED TO BE STORED IN THE SAFEGEAR BREAKER

COMPARTMENT.

TYPICAL OPERATING PROCEDURE FOR GROUNDING THE CIRCUIT BREAKER:

1.

DISCONNECT THE GROUND CABLES FROM ALL TERMINALS

2.

SWING DOOR OVER THE DEVICE TERMINAL SET THAT IS NOT TO BE

GROUNDED.

3.

PADLOCK THE DOOR IN THIS POSITION.

4.

INSTALL THE DEVICE IN THE SAFEGEAR COMPARTMENT.

5.

CLOSE AND SECURE THE SAFEGEAR DOOR.

6.

RACK THE DEVICE TO THE FULLY CONNECT POSITION. THE DEVICE MUST BE

IN THE FULLY CONNECT POSITION. THE “CONNECT” LABEL MUST BE IN THE

APPROPRIATE POSITION TO ASSURE THAT THE DEVICE IS INSTALLED PROP-

ERLY.

7.

OPEN THE SAFEGEAR DOOR.

8.

TEST THE EXPOSED TERMINAL ENDS TO ASSURE THAT THE TERMINAL SET TO

BE GROUNDED IS NOT ENERGIZED.

9.

AFTER ESTABLISHING THAT THE EXPOSED TERMINAL SET IS DEENERGIZED,

CLOSE THE SAFE GEAR DOOR AND RACK THE DEVICE TO THE DISCONNECTED

POSITION.

10.

OPEN THE SAFEGEAR DOOR WITH THE DEVICE IN THE DISCONNECTED POSI-

TION. ATTACH THE UPPER OR LOWER GROUND CABLES TO THE EXPOSED

TERMINAL SET.

11.

WITH THE GROUNDED CABLES ATTACHED, CLOSE AND SECURE THE SAFE-

GEAR DOOR AND RACK THE DEVICE TO THE “CONNECT” POSITION.

12.

WITH THE GROUND CABLES INSTALLED AND THE DEVICE RACKED TO THE

“CONNECT” POSITION, THE TERMINAL SET CONNECTED TO THE GROUND CA-

BLES IS GROUNDED TO THE SAFEGEAR GROUND BUS.