65

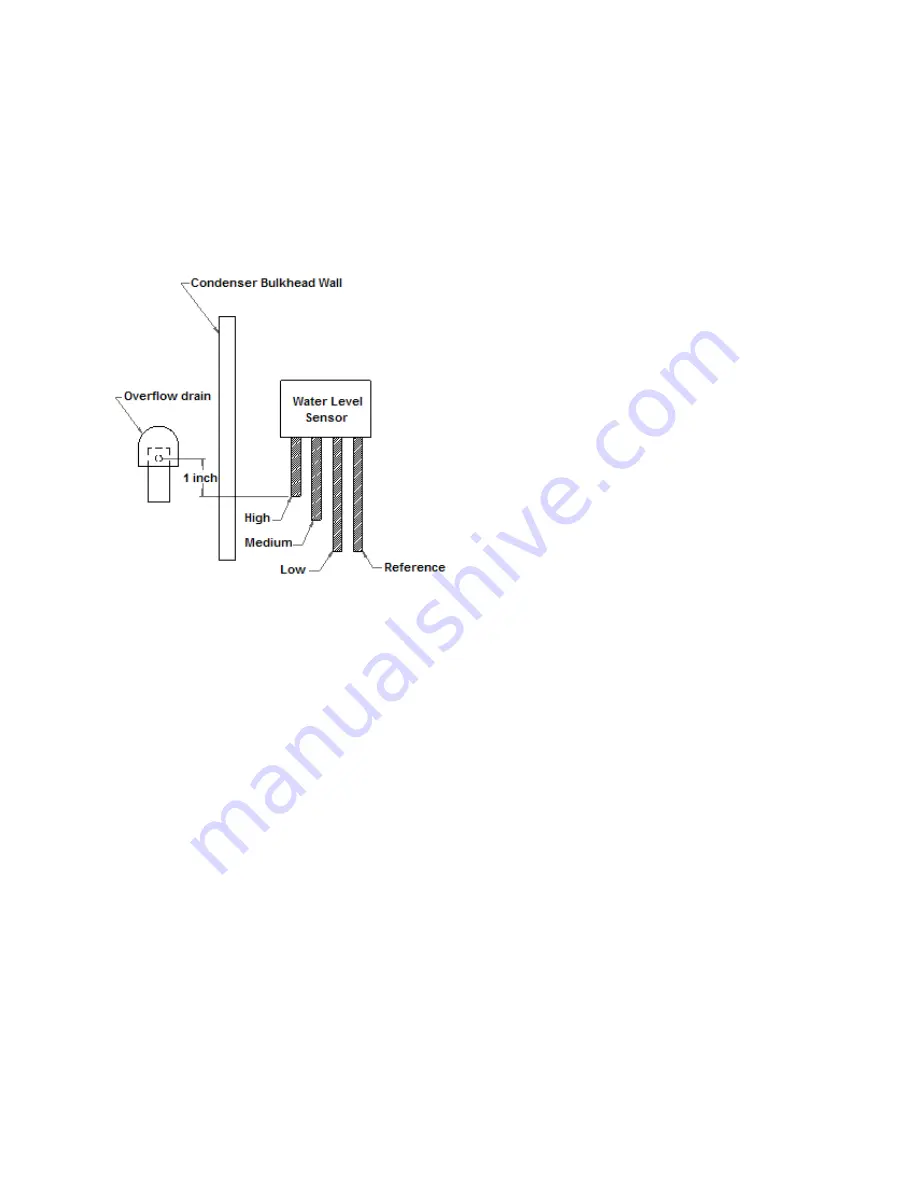

gets to the medium water level. In normal

operation, the water level should swing

between the medium and high water levels.

The maximum high water level should be 1”

below the overflow drain which occurs after

the makeup water valve shuts off when the

water level reaches the high level probe.

Figure 35 - Water Makeup Valve

Make up water supply pressure should be

maintained between 15 and 60 psig for proper

operation of the valve. The makeup water

valve assembly should be inspected monthly

and adjusted as required. Replace the valve

seat if leakage occurs when the valve is in the

closed position.

Water Treatment System

All AAON evaporative-condensed chillers

come equipped with a water treatment system

that should be maintained by a local water

treatment professional trained in the water

treatment of evaporative-condensed chillers.

This system consists of a controller, three

chemical pumps and storage tanks, a

conductivity sensor, a motorized ball valve

for water bleed and a water meter.

One chemical pump and tank is typically

used for a de-scaling chemical to prevent

scale from forming in the condenser. The

other two pumps and tanks are typically used

for two different biocides (to kill any

microorganisms that could grow in the

condenser). Two biocides are used to prevent

organisms from becoming resistant to one

chemical.

The mineral content of the water must be

controlled. All make up water has minerals in

it. As water is evaporated from the condenser,

these minerals remain. As the mineral content

of the water increases, the conductivity of the

water increases. The water treatment

controller monitors this conductivity. As the

water conductivity rises above set point, the

controller will open a motorized ball valve on

the discharge side of the condenser pump and

dumps water into the condenser drain until

conductivity is lowered. While the motorized

ball valve is opened, the controller will not

disperse chemicals.

The chemicals are dispersed by the water

treatment controller based on the scheduled

input by the water treatment professional.

The water meter measures the quantity of

makeup water used by the condenser.

Any water treatment program must be

compatible with stainless steel, copper,

aluminum, ABS plastic and PVC. Batch feed

processes should never be used as

concentrated chemicals can cause corrosion.

Never use hydrochloric acid (muriatic acid)

as it will corrode stainless steel.

Sequence of Operation for LZ Series units

without Diagnostics

On a call for cooling, the condenser pump is

activated. A pressure switch in the pump

discharge is bypassed for six seconds by a

time delay relay in order for the pump to

establish recirculating water flow. If flow is

not proven within the six seconds, the

pressure switch opens, breaking the safety

Summary of Contents for LZ Series

Page 2: ......

Page 27: ...27 Figure 6 Concrete Pad Mounting with Dimensions Figure 7 LZ Base ...

Page 36: ...36 Figure 17 Typical Flue Vent Piping ...

Page 83: ...83 ...

Page 84: ...84 ...

Page 95: ...95 Flo Trex Cross Section ...